Introduction: Unlocking Precision with Lab Dip Approval and Strike-Offs

In the intricate world of apparel manufacturing, color is not just an aesthetic choice—it’s a foundational quality indicator. Mastering Color Control for Apparel: Lab Dips & Strike-Offs is essential for brands determined to deliver what buyers expect. This article explores the difference between lab dips and strike-offs, explains industry-standard tolerances, and provides expert tactics to minimize shade variation. By aligning corporate, design, and factory teams, you’ll avoid costly re-dyeing and build a reputation for reliability starting at sample stage.

Understanding the Key Terms: Lab Dip Approval vs. Strike-Offs

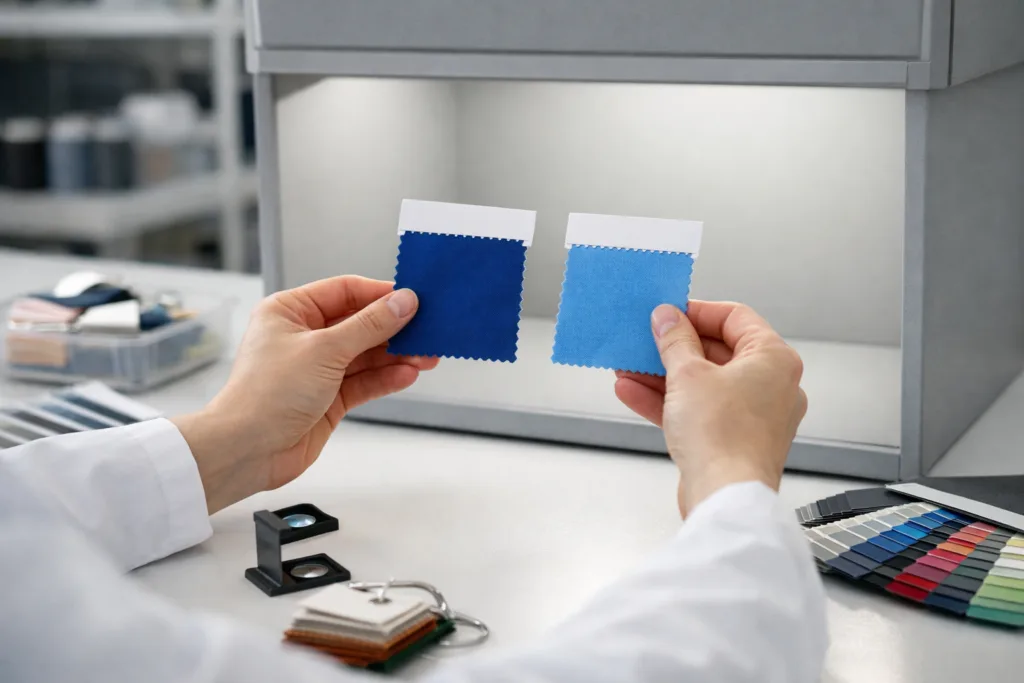

Lab dip approval refers to the process of checking and confirming the dyed fabric swatch’s color before bulk production. A lab dip is a small sample dyed to match a specified shade. A strike-off is a printed or woven swatch used mainly for prints or yarn-dye fabric. While both serve to verify color accuracy, lab dips focus on solid dye shades, and strike-offs address patterns, placements, and overall color impression in prints or jacquard weaves.

Why Precise Color Control Matters in Apparel Production

From brand storytelling to customer satisfaction, even minor color inconsistencies can mean garment returns, loss of customer trust, and extra production costs. Brands who internalize this avoid surprises, anchored by disciplined color approval at sampling stage.

Lab Dip: Purpose, Workflow, and Industry Practices

A lab dip is a dyer’s preliminary attempt to match the requested color standard. The factory technicians mix dyes and produce several swatches, typically on the intended base fabric for production. These are reviewed under controlled lighting conditions, like D65 or TL84, and marked with batch numbers for reference. A key factor: the final approved lab dip sets the reference for bulk dyeing.

Sample Preparation: Best Practices

The dyer should use actual production fabric, not substitutes. This avoids shade shifts caused by different fiber content or finishes. For example, cotton jersey and cotton fleece can display the same dye formula differently.

Strike-Offs: Definition, Use Cases, and Approval Steps

Strike-offs are critical in print, jacquard, and yarn-dyed styles. They allow the brand to check color placement, sharpness, and pattern repeat prior to mass production. Unlike lab dips, which check a flat shade, strike-offs reveal how multiple colors work together, often influencing perceived panel colors.

Comparing Lab Dip and Strike-Off

| Feature | Lab Dip | Strike-Off |

|---|---|---|

| Material | Dyed solid fabric | Printed/woven/jacquard sample |

| Main Use | SOLID color approval | PRINT/PATTERN color + design check |

| Approver | Brand/Designer | Brand/Designer |

| Bulk Reference? | Yes | Yes |

| Common Application | T-shirts, polos, hoodies | Floral dresses, jacquard knits |

Color Tolerance: Industry Standards and Measurement

Color tolerance is the acceptable range of shade difference between the approved sample and the final production lot. Standards vary by market, but Delta E (dE*) values of 1.0–1.5 (using spectrophotometer) are typical. Visual tolerance—often called “commercially acceptable matching”—is vital, since real-world environments differ from lab conditions. Brands should specify both instrumental (numeric) and visual (human) standards to reduce disputes.

Visual vs Instrumental Assessment

- Instrumental: Spectrophotometer measures color distance (ΔE)

- Visual: Assessed under controlled light box by trained personnel

For garment brands seeking tight control, review the detailed sample approval process workflow for step-by-step instructions on integrating color checks early on.

Sources of Shade Variation: Production Risks and Realities

Color deviation can stem from multiple sources:

- Dye batch inconsistency

- Water quality and temperature fluctuation

- Fabric pre-treatment differences

- Lighting and surface humidity during sampling

Factory Insight: Ninghow’s Experience with Controlled Lab Dips

At Ninghow, lab dip issues are most common when base greige fabric lots vary slightly in absorbency or finish. Dyers keep detailed records so that even when multiple dye baths are needed, the formula remains tightly controlled. If labs dip approvals drift by more than Delta E 1.5, it’s back to mixing—preventing major problems later.

Minimizing Color Variation: Proven Strategies for Apparel Brands

How do you reduce shade variation and minimize rejects?

- Consistent base material: Source the same greige fabric lot for bulk and sampling.

- Standardized dye formulas: Insist on written formula records and reference samples.

- Controlled lighting: Compare samples in a professional light box using D65/Daylight and TL84.

- Clear approval: Mark all approved lab dips and keep records for bulk reference.

- Repeat checks: Spot-check bulk fabric to ensure shade aligns with approved dip.

- Collaborative review: Involve both QC and brand/factory in the approval process to ensure consensus.

For more on matching fabric handfeel and performance, see Fabric & Trim Sourcing: 7 Secrets to Match Handfeel & Performance.

Color Matching Tools: Modern Solutions for Accuracy

Spectrophotometers, colorimeters, and light boxes are now standard in larger factories. Handheld devices allow brands to record and transmit precise numeric standards to suppliers, minimizing cross-factory miscommunication.

Digital Approvals: Pros and Pitfalls

While digital color charts and remote approval processes save time, they can’t fully replace physical sample review—monitor displays and ambient lighting can mislead decision-makers. Always confirm with a physical swatch before approval.

Critical Steps in Lab Dip Approval: From Request to Sign-Off

- Brand provides color standard (Pantone, fabric swatch, or print artwork)

- Factory prepares lab dips with various dye formulas

- Brand reviews dips under specified lighting

- Approved dip is signed, marked, and returned to factory

- Factory retains a copy for bulk dye reference

- QC checks bulk fabric before and after dyeing

The step-by-step method detailed above is crucial for avoiding headaches in bulk production. For an end-to-end workflow, explore the private label clothing development checklist.

Common Mistakes That Cause Color Problems

- Approving lab dips on different fabric quality than bulk (mismatched fiber/fabric type)

- Using inconsistent light source for color review

- Failing to record or sign approved shade swatch

- Ignoring small shade variation that becomes obvious on finished garments

- Confusing lab dip with strike-off in approvals (solid vs pattern)

- Not controlling bulk dye bath variables

Lab Dip vs Strike-Off: How the Difference Impacts Quality Control

The distinction is more than academic. Lab dip approval sets a single shade benchmark, vital for solid color production. Strike-offs allow brands to check multiple color interactions and pattern clarity, essential in fashion items with high print content.

Practical Workflow Example: Polo Shirt vs Jacquard Hoodie

- Polo Shirt (Solid): Lab dip for pantone-matched color. Approval ensures bulk shirts match brand standard.

- Jacquard Hoodie (Pattern): Strike-off checks both ground and motif colors, guaranteeing the design looks as intended once produced at scale.

Optimizing Approval Speed: Reducing Delays in Sampling and Bulk

Tight schedules are a reality. Brands can reduce lead times by:

- Sending clear color standards upfront

- Responding quickly to factory lab dips

- Allowing for slight tolerances where commercial acceptability won’t impact sales

- Pre-communicating tolerances and approval authority (designer vs buyer vs QC)

Communication Protocol: Factory-Brand Collaboration for Fewer Errors

Open dialogue determines whether errors are caught before mass production. Factories like Ninghow maintain clear approval records, store physical swatches, and update digital logs to facilitate rapid troubleshooting. For proven communication tips, see Supplier Communication SOP for Apparel Production.

Bulk Production: Maintaining Color Consistency Across Lots

Shade matching doesn’t end at the approval stage. Factories must monitor each dye batch to ensure alignment with the original lab dip or strike-off. On large orders, separate lots should be cross-checked and blended if deviation approaches tolerance limits.

Returns and Claims: The Risks of Color Mismatch

Unacceptable shade difference can trigger costly claims and returns. Brands are wise to record every approval step and set clear negotiation terms in purchase orders, protecting margins and reputation.

Best Practices for Avoiding Color Issues in Garment Production

These strategies transform color control from risk to competitive advantage:

- Always use production fabric for lab dips

- Review samples under consistent, controlled lighting

- Set numeric and visual color tolerances

- Retain approved dips/strike-offs until delivery

- Spot check bulk lots and keep open dialogue with factory

Case Study: How Lab Dip Approval Cut Color Complaints by 80% at a Mid-Sized Brand

One fashion brand changed its lab dip review process by specifying tolerances and storing reference swatches. In one season, returns triggered by shade issues fell from 10% to 2%—highlighting the payoffs of disciplined color approval.

Integrating Color Control into Apparel Product Development

The sooner brands implement these control points—alongside pattern accuracy and trim sourcing—the smoother production flows. Lab dip approval isn’t a bottleneck if viewed as a productivity tool rather than a compliance hurdle.

Color Control for Apparel: Lab Dips & Strike-Offs

Managing shade, tolerance, and approval workflow is non-negotiable in modern fashion manufacturing. By understanding the differences between lab dips and strike-offs, defining attainable color tolerances, and collaborating closely with factories like Ninghow, brands reduce color inconsistencies and rework, saving time and money. Tighter color control not only safeguards your reputation, but also signals operational excellence in every finished garment.

Frequently Asked Questions

What is the main difference between lab dip and strike-off?

A lab dip is a dyed fabric swatch for solid color approval, while a strike-off is a sample used for print or pattern color and design verification.

How is color tolerance set in the apparel industry?

Brands set color tolerance by specifying visual acceptability and numeric measurements, often using Delta E values and light box assessment.

Can digital color approval replace physical samples?

Digital approval can speed up review, but it cannot fully replicate real fabric evaluation; physical samples remain essential for final decisions.

Why do color inconsistencies occur after lab dip approval?

Shade variation can result from differences in fabric, dye batch, water quality, and uncontrolled production variables that weren’t present in sampling.

What steps help minimize color variation in bulk production?

Use the same fabric lots, record dye formulas, review all samples under controlled lighting, and spot-check bulk output against the approved samples.

How can brands speed up lab dip approvals without sacrificing accuracy?

Brands should provide clear standards, respond quickly, communicate tolerances, and encourage collaborative reviews for efficient turnaround times.

Related Reading

- How to Launch Hoodies Rapidly: Timeline & Critical Path Insights

- Eliminate Costly Fit Revisions: Pattern & Sizing Solutions You Need

- QC Reporting Masterclass: 9 Fields Factory Must Share for Zero Surprises

- Apparel Returns Playbook: Control Points to Slash Defects and Disputes

- Master Apparel Sampling: Types & Tactics From Proto to Production