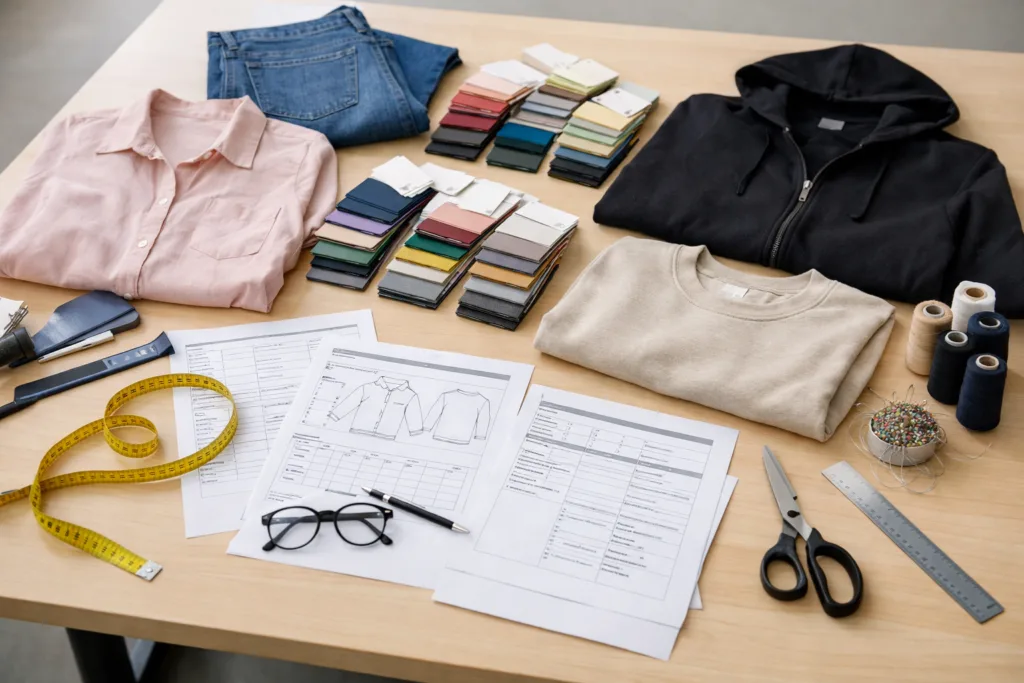

Introduction: Why Approving PPS Matters More Than Ever in 2026

Approving a Pre-Production Sample (PPS) is a key milestone for every apparel brand, whether you’re launching your first line or scaling up a seasoned collection. Understanding how to approve PPS like a pro doesn’t just keep your timeline on track—it’s the main defense against costly mistakes, late deliveries, and customer disappointment. A thorough pre production sample checklist bridges the gap between beautiful tech packs and real-world factory output, helping brands avoid the nightmare of mass production defects and inconsistency.

What is a Pre-Production Sample (PPS)?

A pre-production sample (PPS) is the prototype garment approved before your supplier begins bulk manufacturing. It verifies trims, fit, fabric, construction—everything you expect from the final product. The PPS locks in your “golden standard,” so every production piece matches your vision.

The Critical Order: PPS Inspection Sequence Explained

Following the right order in your PPS inspection ensures nothing slips through the cracks. Start with documentation (spec sheets, PO, color standards), then check materials, construction, and packaging. Reviewing details in a logical flow—rather than jumping between sections—makes it easier to catch errors before they cascade into production. Many top brands build inspection templates based on proven inspection sequences. (Learn how production timelines tie in with the PPS stage.)

Checklist Item 1: Signing Off Tech Packs and Sample Files

Your PPS approval should always reference a signed-off tech pack, spec sheet, and original design documents. Attach any prior sample notes, photographic references, and correspondence. This anchors approval to actual expectations, reducing the risk of miscommunication.

Checklist Item 2: Confirming Fabric and Trim Consistency

Inspect all fabrics and trims used in the PPS match lab dips, hand feel, GSM, and supplier test reports. Even seemingly minor mismatches (wrong zipper or button size) can multiply during bulk production. At Ninghow, we often remind clients: What you sign off here is what will appear in every carton. Shortcuts now are painful fixes in bulk.

Checklist Item 3: Verifying Construction, Stitching & Seam Strength

Assess seam alignment, SPI (stitch per inch), thread quality, and reinforcement details. Periodically, brands do a hands-on durability spot test (seam pulls, minor stretching) at this stage, supported by step-by-step methods like those in our seam strength test guide.

Checklist Item 4: Embellishments, Printing, and Embroidery Quality

If your products feature print, embroidery, or heat transfers, review their sharpness, durability, and placement. Use established visual standards for print quality and embroidery density. For deeper insights, our print & embroidery quality guide is a useful resource at this stage.

Checklist Item 5: Color Fastness and Shrinkage Tolerance

Request colorfastness and shrinkage test results for main fabrics, especially on high-contrast colorways. Deviations here impact fit and appearance post-wash. Proactive brands ask for supporting data, as summarized in the shrinkage & colorfastness guide for buyers.

Checklist Item 6: Measurement and Fit Accuracy

Double-check all garment measurements against your size spec. Lay each piece flat and measure key POMs (points of measurement). Document any tolerances and clarify them with your factory. This prevents bulk mistakes that pile up—literally—in your warehouse. (See also: garment measurement tolerance strategies.)

Checklist Item 7: Labels, Compliance, and Packaging Review

Verify all labels, hangtags, care instructions, and folding methods. Are materials and washing instructions correct for target markets? Compliance for fiber content, labeling laws, and consumer safety shouldn’t be afterthoughts in 2026. Your ability to move stock without hold-ups depends on nailing these details early.

Comparing PPS Against Reference Samples: Spot the Red Flags

Physically compare your PPS with “golden” reference samples (from past orders or trusted sources). Watch for telltale signs: mismatched shade, off-spec placement, or inconsistent hardware. If differences are borderline, document them formally so everyone—factory and brand—works from one agreed playbook.

Common Pitfalls: Why PPS Approvals Go Wrong

Even experienced teams hit snags. Rushed approvals, undefined tolerances, and skipped paperwork often lead to bulk deviations. Setting clear, unambiguous standards—then sticking to your pre production sample checklist—is what separates seasoned veterans from the rest of the field.

The Golden Sample: Locking in Your Approval Standard

Once you approve a PPS, mark it as the “golden sample.” Both your team and the factory must reference this for every quality and measurement check. At Ninghow, we store signed PPS and digital documentation to close the loop between sampling and production, minimizing disputes later on. This habit, simple as it sounds, is a game-changer for consistency.

How to Approve PPS Like a Pro

Pro-level PPS approval balances attention to detail with risk management. Here’s what experienced buyers do differently:

- Schedule in-person or live video PPS inspections when possible

- Photograph all angles and details for digital records

- Mark and sign every correction on the QC report

- Use physical markers (tags, stickers) on the actual sample to flag issues

- Only approve when ALL checklist points are passed—never under pressure

Documenting Your Approval: The Importance of Clear Records

Document everything—approvals, rejections, change requests, and signed golden samples. Attach annotated photos or videos when possible. This creates a verifiable trail of standards for each production run in 2026 and beyond.

PPS vs TOP Samples: What’s the Difference?

PPS is your pre-production check, typically made before production starts. TOP (Top of Production) samples come from the first units off the line. Approving both helps catch last-minute process changes or material substitutions that may slip in after PPS is signed off.

Managing Revisions: Handling a PPS That Fails

If the PPS misses requirements, clearly note all issues and request corrections. Rejections should be detailed and solution-oriented. Don’t compromise if critical elements are wrong—approve with conditional comments only for low-impact, non-customer-facing aspects. On average, brands build in time for 1-2 revision rounds per style.

What Happens Next? Finalizing Bulk Approval

Once the PPS is approved, inform your factory in writing, attach all documentation, and update your project tracker. This triggers raw material booking and bulk production scheduling. If your timeline is aggressive, ask for inline QC and extra checks during first shipment packs.

Key Differences When Sourcing Internationally

International suppliers may interpret standards differently. Use clear photos, detailed SOPs, and explicit signoffs. Build in time for customs clearance and lab testing if needed. Effective communication—like the tips found in supplier SOP guides—is vital at this stage.

How Top Brands Prevent PPS Approval Issues

Leading brands invest in comprehensive checklists, proactive communication, and digital recordkeeping. They coach their suppliers on expectations, use comparison samples, and favor a collaborative, not adversarial, approach to correction requests.

Syncing PPS Approval With Your Production Timeline

Align your PPS approval with booking deadlines, material ordering, and shipping slots. Delays here can create a knock-on effect across the entire supply chain. Use tools and project management trackers to keep milestones visible and on pace.

Troubleshooting: When PPS and Bulk Don’t Match

If bulk doesn’t match the approved PPS, treat your documented standard as your baseline. Share evidence with the supplier and negotiate corrections or rebates if quality falls short. It’s critical to stop shipment until everyone agrees on a solution to prevent customer returns and reputation damage.

Digital Solutions: Using Tech to Streamline PPS Checklist and Approvals

Modern brands increasingly use digital tools—app-based checklists, virtual sampling platforms, remote video approval—to bridge distance and keep approvals objective. This helps especially when teams are distributed or travel is limited.

The Role of the Factory: Why Collaboration Wins

Your factory’s willingness to listen and adapt affects how smoothly the PPS process runs. At Ninghow, sharing photos, fit notes, and post-approval summaries with the client results in fewer disputes and faster production launches.

Template: Sample Pre Production Sample Checklist

| Checklist Item | Status | Comments |

|---|---|---|

| Tech pack / spec signed | Pass/Fail | File attached |

| Fabric & trim match | Pass/Fail | Tested sample swatch |

| Construction/stitching | Pass/Fail | Photos added |

| Printing/embroidery | Pass/Fail | Colorfast test Y/N |

| Garment measurements | Pass/Fail | Tolerance listed |

| Labels/compliance | Pass/Fail | Photos checked |

| Packing method | Pass/Fail | Drop test done? |

| All corrections signed | Y/N | Final PPS signoff |

Conclusion: Pro-Level PPS Approval Reduces Costly Surprises

Approving your pre-production sample isn’t just paperwork—it’s the single best way to avoid miscommunication, reduce returns, and guarantee your vision goes from tech pack to finished garment. A step-by-step, practical pre production sample checklist and collaborative spirit pay off with consistent results and stress-free production. Set clear standards, document everything, and you’ll approve PPS like a pro—year after year.

Frequently Asked Questions

What happens if the PPS doesn’t match my requirements?

Communicate all issues clearly to your supplier with supporting photos and request a revised sample. Approve only when all issues are corrected.

Should I approve a PPS with minor issues?

Never approve a PPS with unresolved critical issues. For minor, non-customer-facing problems, approve with remarks, but be clear on exceptions.

How many times can I request a revised PPS?

Most suppliers accept 1–2 revision rounds per style, but communicate early if you expect extra changes. Build this into your timeline.

Do I need to approve TOP samples after PPS?

Yes, reviewing TOP (Top of Production) samples helps confirm that bulk garments align with the approved PPS, especially with fabric or process changes.

How do I make sure the bulk matches the PPS?

Use detailed documentation, signed golden samples, and ongoing production QC checks. Stop shipment if major mismatches are found.

What’s the biggest mistake brands make in the PPS process?

Rushing approval or skipping parts of the checklist, leading to major problems in bulk production. Be thorough and methodical.