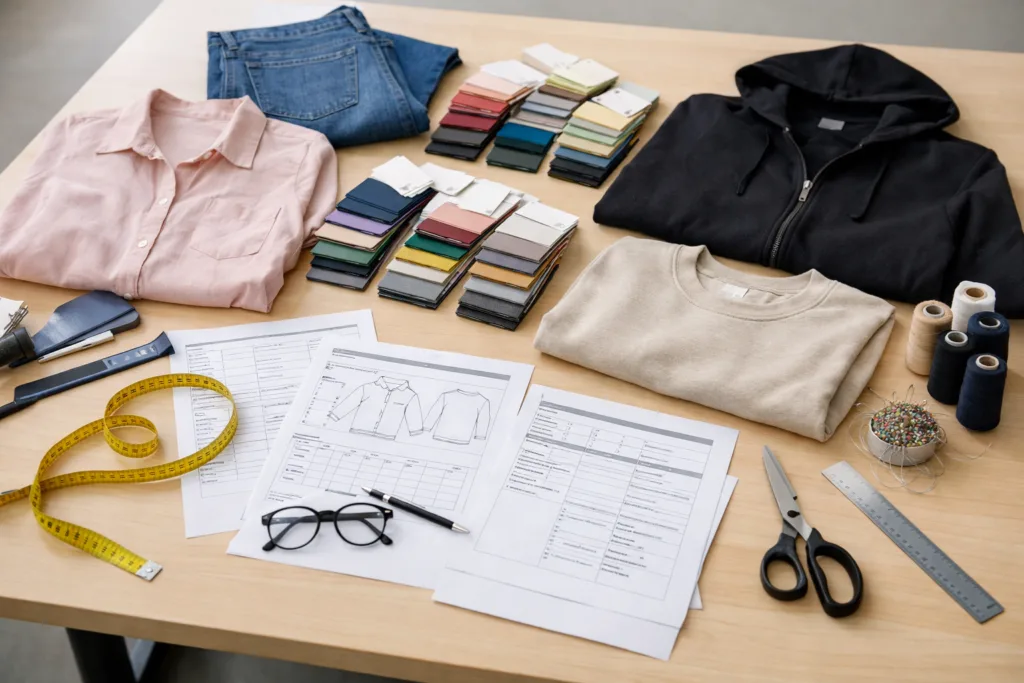

The Actionable Returns Reduction Playbook for Apparel Brands: Control Points from Pattern to Packing

Introduction: Why Returns Matter and How the Right Playbook Tackles Them Returns have quietly become one of the costliest headaches for fashion brands. With each returned garment, profits shrink and reputation suffers. The crux? Most apparel returns aren’t random—they stem from predictable issues throughout the supply chain. In this Returns Reduction Playbook: From Pattern to […]