Introduction: Why Pattern Making & Fit Matter More Than Ever

Getting your garment pattern making and fit right is the make-or-break stage in apparel production. Even a sharp design or premium fabric won’t help if a brand stumbles here. Every revision costs time and money. Worse, poor fit invites returns, negative reviews, and drains your profit. In this guide, discover proven strategies to reduce costly revisions, write targeted fit feedback, and minimize frustrating trial-and-error.

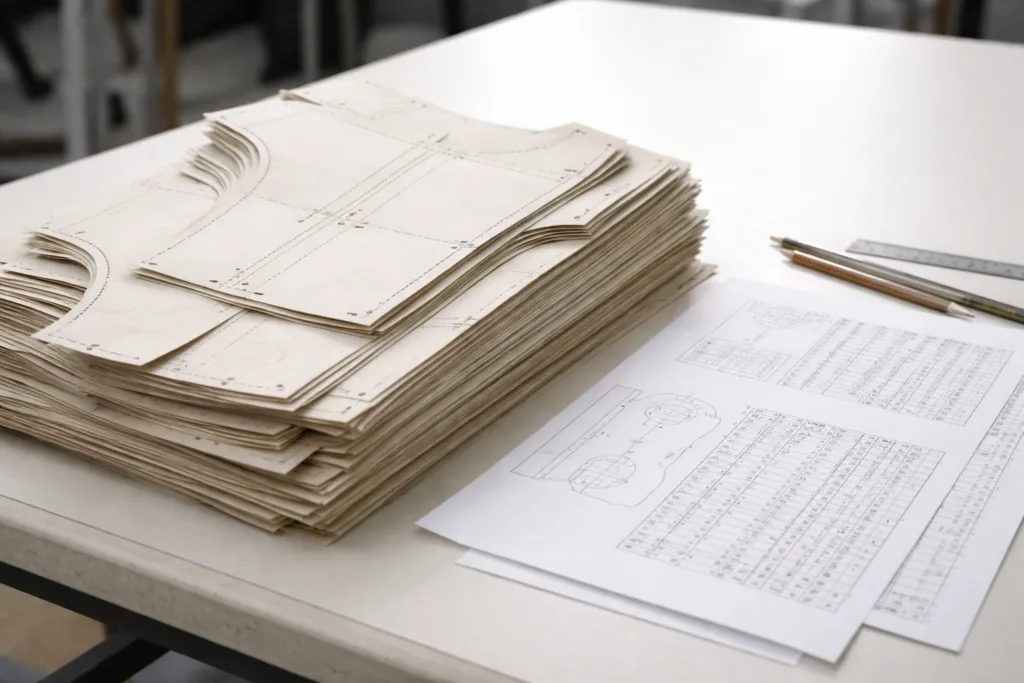

Understanding Garment Pattern Making Essentials

Garment pattern making translates a designer’s concept into repeatable templates. These guides—made of paper, card, or digital files—control every part’s size and shape from prototype to bulk cutting. Mastering this process is crucial for avoiding headaches downstream. If you’re new to apparel, also read about matching fabric handfeel and performance to support pattern decisions and successful first samples.

How Pattern Making Fits Apparel Development

Pattern making sits between design sketches and actual sample sewing. It’s when the 2D dream turns into something a factory can stitch in 3D. A seasoned pattern maker will adjust for fabric stretch, stitching techniques, and garment function. Get this phase right, and you’ll prevent cycles of awkward samples and emergency tweaks.

Common Causes of Costly Revisions

What triggers repeated pattern changes and costly delays?

- Vague or incomplete style specifications

- Unrealistic reference samples (“make it like this, but slimmer”)

- Lack of actual fit sessions with your target size

- Ignored feedback from sewing or QC teams

- Changes in fabric, trims, or construction after pattern approval

Addressing these issues from the start is essential if you want a clean, predictable process.

Reducing Revision Cycles: Factory-Proven Strategies

Avoiding rework begins with clarity. Here are actionable strategies:

- Provide clear tech packs with precise measurements

- Share fabric details early (GSM, stretch, shrinkage)

- Hold fit sessions using real target customers or reliable models

- Log every change and approval in writing

- Approach each pattern from an end-to-end garment flow perspective—not isolated pieces

If you need a practical roadmap, check out the winning sample approval workflow for brands to see how established manufacturers coordinate these steps and minimize surprises.

The Logic of Pattern Modification: Step-by-Step Process

Good pattern modifications follow a logical, systematic flow. Here’s a template for making objective, trackable changes:

- Identify the precise issue (e.g., chest too tight, sleeve drop too low)

- Trace the possible pattern piece and measurement involved

- Decide: adjust seam, fullness, or total measurement?

- Test with a marked sample or paper overlay—never “wing” it

- Document the change, even if it’s small

- Revise patterns with version numbers and restrict edits to one variable at a time if possible

Best Practices for Writing Clear Fit Feedback

Honest, focused fit feedback helps your pattern technician or supplier know exactly what’s wrong—and what’s working well. Effective feedback should:

- Use plain language with body part references (“waistband digs in” beats “not comfortable”)

- Describe the experience (“torso rides up when raising arms”)

- Reference the visual—photos marked with arrows or highlight tape can be transformative

- Offer a suggestion only if you’re sure; otherwise, ask your pattern maker’s advice

- Avoid “over-prescribing”; trust experts where possible

Sample Fit Review: How to Structure Feedback

Every fit review should produce a short, structured report. Here’s a proven outline:

| Body Area | Issue Observed | Suggested Action | Image Ref. |

|---|---|---|---|

| Shoulder width | Tight across back | Add 1cm per side | Pic 2 |

| Hem opening | Too loose | Reduce by 2cm | Pic 3 |

| Sleeve length | Just right | No change | Pic 4 |

Standard Fit Issues and Root Causes

- Bust or chest too tight: Pattern not accounting for fabric type or stretch direction

- Neckline gapes: Too much seam allowance or incorrect angle

- Sleeves twist: Cap shape error or alignment mismatch

- Torso rides up: Short front/back length, misapplied pattern grading

Evaluating Success: Pass/Fail Criteria for Each Fit

Each fit sample should have objective pass/fail benchmarks. Examples include:

- Waist measures within +/- 1cm tolerance of spec

- Side seams vertical on body

- Comfort with movement (sit, walk, reach)

- No visible pulling or drag lines

Don’t settle for “feels about right”—be precise.

How Brands Like Ninghow Keep Fit Consistent

At Ninghow, a pattern is never “one and done.” Each style begins with a fit session on the agreed fitting body, plus cross-checks on factory mannequins. All pattern changes are documented, and new samples include both requested and optional expert suggestions. This reduces surprises at bulk production and leads to fewer returns—a practice anyone can adopt by staying disciplined and tracking fit history.

Pattern Grading Fundamentals for Sizing Up/Down

Pattern grading ensures your fit scales up and down without distortion. Good grading records base style measurements and increases key points by standard increments. Poor grading creates awkward proportions and inconsistent customer experiences—leading to more size-based complaints and returns.

Fabric & Trims: Their Role in Pattern Adjustments

Choosing a fabric heavier, lighter, or stretchier than your sample can derail a pattern. The same goes for trims; a thick rib or bulky zipper changes tension and fit. Lock all materials before finalizing the pattern, or note “flex” in your fit review. For expert materials tips, see fabric and trim sourcing secrets.

Reducing Rework Through Precise Sample Types

Not all samples are alike: proto, fit, photo, size set, and pre-production each serve a unique purpose. Skipping or confusing these steps triggers more corrections. See how to master apparel sample types for an inside look.

Cost Implications of Revision Rounds

One back-and-forth may feel minor but multiplies fast in staff hours, lost fabric, delay charges, and later QC risk. Map your actual costs per revision—it’s often higher than most brands anticipate. Minimizing changes at the pattern stage has a major bottom-line impact.

Digital Pattern Making: Pros and Cons

Today, many factories use digital pattern software for speed and accuracy. The advantage: instant grading and easier sharing. The drawback: it’s only as good as the measurements and initial fit review. Don’t let digital convenience replace human fit checks and hands-on feedback.

Trial Fittings: Organizing for Objective Feedback

How you run fit sessions influences the quality and clarity of revisions.

- Use live models matching your target market—not staff “stand-ins”

- Set up full-length mirrors, consistent lighting, and record video as needed

- Get feedback from at least two people: tech/design side and “normal” wearers

Documentation: Tracking Pattern History and Changes

Keeping a change log with date, version, and detailed notes prevents confusion and repeated mistakes later. Whether paper or digital, don’t skip this admin step: your future self (and your supplier’s) will thank you.

Measurement Charts: Tolerance and Control Methods

All measurements require tolerance bands (e.g., +/- 0.5 cm). Communicate these in your tech pack and fit reviews to prevent unnecessary panics for marginal differences, and see precision tolerance strategies for 2026 for practical measurement advice.

Integrating Fit Feedback in Future Production Runs

Don’t let valuable feedback end up forgotten. Record what worked and what didn’t, then review before each reorder or style refresh. Include actual wearer comments, not just numbers, for robust long-term improvement.

Partnering with Pattern Makers: Communication Tips

Successful brands build open, detail-rich relationships with their pattern team. Share sketches, annotate photos, ask “why” for any suggested change. Good pattern makers want context—keep channels open and avoid adversarial tone.

Quality Control Cross-Check Before Bulk Production

Before cutting big quantities, run a QC cross-check. Confirm all approved changes made it into final patterns and that samples reflect actual production fabric, trims, and construction. For a sample QC reporting template, refer to top industry tools for structured review.

Version Management: Staying Organized Through Multiple Styles

Whether a fashion line or uniforms, robust version control (file naming, date, revision ID) prevents mixups that can torpedo a production run. Don’t use “finalFINAL” as your only cue—formal process matters.

How Pattern Decisions Impact Garment Returns

Poorly fitting items drive returns and customer complaints. Precise patterns, tested fit, and honest revision management reduce issues at the root, directly improving customer loyalty and profits. For actionable tips, visit the returns reduction playbook.

Pattern Making & Fit: Avoid Costly Revisions

Making accurate garment patterns and fit feedback your superpower will stop the endless cycle of changes. Apply structured modification logic, document feedback, involve the right stakeholders in trial fits, and formally track revisions. Over time, you’ll see fewer errors, less rework, and a more reliable supply chain that lifts your margins and reputation.

Frequently Asked Questions

What is the first step in garment pattern making?

The first step is to analyze the style, confirm measurements and sketches, and select the correct base pattern (block) for developing the design.

How should I write effective fit feedback for samples?

Write objective, body-region-based comments with supporting photos or sketches, focusing on facts rather than vague impressions.

How do fabric choices impact pattern adjustments?

Fabric type affects stretch, drape, and shrinkage, which can alter fit and require pattern tweaks. Always confirm fabric before finalizing patterns.

When should a sample be revised versus accepted?

Revise if measurements fall outside tolerance or fit is visibly poor. Accept minor issues within tolerance if the overall fit meets your requirements.

What’s the most common fit problem in bulk production?

Small pattern changes not documented or applied consistently, leading to surprise fit issues and returns at delivery.

How can I reduce rework and revision costs?

Start with detailed specs, organize fit reviews, document all changes, and communicate clearly with pattern makers and factories before bulk production.