Why Circular Sportswear Design Matters

Sportswear should fuel performance while also protecting the planet. The fashion industry generates over 92 million tons of waste and is a top polluter globally. The solution: circular design. Circular sportswear design means making products with repair, reuse, and recycling in mind from the start. It involves choices in fabric, trims, construction, and post-use systems—all aimed at extending the life cycle and minimizing landfill.

From pro teams to fitness enthusiasts, more buyers demand gear that’s both high-performance and lower-impact. Brands using circular methods show commitment to sustainability, boost trust, and build long-term value.

Circular Sportswear Design

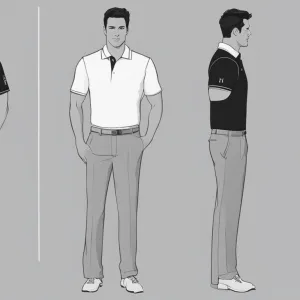

What sets circular sportswear apart from traditional gear? The key is engineering for repairability, modularity, and full end-of-life planning. Sportswear designed for circularity is easier to fix, easier to disassemble, and can be recycled or safely returned to nature at the end of its useful life. Apparel manufacturers like Ninghow integrate these principles when creating sports polos, joggers, training tees, and more.

Practices include using fewer mixed materials, choosing trims that snap or zip off, and ensuring every label and zipper is considered for its recyclability and removal. The result: sportswear that not only performs but also supports a future where clothing doesn’t become waste.

Mono-Material Strategy: The Power of Simplicity

A mono-material garment uses only one main fiber, for instance, 100% polyester or 100% cotton, throughout. This is crucial for recycling. Separating blends—like cotton/poly—at end-of-life remains a major challenge for recyclers. Instead, building a running shirt or hoodie from one fiber type (including collars, threads, and trims) greatly improves recycling rates and yields higher-quality new fibers.

| Material Strategy | Properties | Best Use Scenarios |

|---|---|---|

| Mono-material (100% polyester) | High recyclability, strong moisture-wicking | Performance tees, track suits |

| Mono-material (100% cotton) | Soft, natural, biodegradable | Training polos, casual sportswear |

| Hybrid w/ removable trims | Mixes performance & comfort, needs trim separation | Specialty jackets, hybrid shorts |

Leading manufacturers source GOTS-certified organic cotton, rPET (recycled polyester), and prefer single-fiber knits for both main fabric and rib collars. Even thread selection (recycled polyester) can support closed-loop recycling.

Modular Trim Design: Easy to Update, Repair, or Recycle

Trims—like zippers, buttons, hook-and-loop fasteners, and snap studs—should never complicate recycling or repair. Modular trims are designed for easy removal and replacement. For example, instead of sewing on a zipper, engineers use snap-in or screw-on systems. This lets athletes replace a zipper or pocket after heavy use without tossing the whole jacket.

- Snap buttons: Allow fast detachment and replacement

- Zipper tracks: Designed for easy separation from fabric, avoiding gluing/complex attachment

- Drawcord stoppers: Can be unclipped and recycled separately

Choosing mono-material trims (e.g., all-polyester zippers on polyester jackets) further boosts recyclability. Modular trims also make custom branding easier—promotional sportswear programs can update logos or details season after season with minimal waste, a practice Ninghow offers in its B2B solutions.

Thoughtful Label & Zipper Choices

Labels and zippers, though small, have big impacts on the recycling journey and daily use. Many brands now use printed care instructions instead of sewn-in labels. When labels are essential, opt for the same material as the garment—polyester on polyester, or cotton on cotton. For zippers and hardware, stick to mono-material options: polyester coil zippers with polyester tape, or metal-free if the end-of-life plan focuses on fiber recycling.

Label Placement and Removal

Labels should sit in places that won’t irritate the skin but also allow easy removal. Laser-cut and heat-transfer methods can reduce physical labels altogether. Wash-away labels, which dissolve in water, aid in both comfort and recyclability.

Zipper Design for Longevity

- Favor high-strength, replaceable zippers like YKK VISLON for athletic jackets

- Avoid adhesives or welds that make separation difficult

- Consider using color-contrasted zippers for easy identification during repair/recycling

Designing for Repairability

Repairability means making it easy for end users or service providers to fix sportswear instead of replacing it. Key approaches include:

- Accessible seams: Double-needle or coverstitch hems that are simple to reopen and restitch

- Reinforced stress points: Bartacks at pockets and openings, allowing repeated use without fabric tear

- Standardized component sizes: Zipper sizes, buttonholes, and snap spacing align with industry norms for easy part sourcing

For example, a running hoodie with a damaged cuff should allow easy removal and reattachment. Brands who offer replacement cuffs or pockets further extend garment life. Ninghow’s manufacturing strategy includes SMV (Standard Minute Value) reviews to ensure new repair points don’t increase production waste.

Take-Back & Recycling Programs: Closing the Loop

The best circular sportswear design doesn’t end at the store—it cycles back. Take-back programs let consumers return used gear when it’s worn out. The products are then sorted for repair, upcycling, or fiber recycling. Effective take-back schemes:

- Communicate clear drop-off or mail-back channels.

- Sort products by condition—some will be repaired for resale, others for material recycling.

- Disassemble mono-material garments with modular trims fastest, lowering recycling costs.

- Use batch ID labels or QR codes to streamline sorting and recycling.

Customer incentives (discounts, membership perks) can boost participation. By weaving take-back capabilities into design and supply chain, companies help close the materials loop and limit waste. Many leading sports brands now build recycling into their product development process rather than as an afterthought.

Recyclability Notes: Technical Design Matters

Circular sportswear design hinges on technical detail. Manufacturers must consider:

- Fabric blend ratios: Pure fibers (100% cotton, 100% polyester) recycle best; blends reduce yield.

- Finishes: Avoid heavy use of non-water-based coatings or foams that block fiber recycling.

- Origin certifications: Fabrics with OEKO-TEX STANDARD 100 or GOTS labels are preferred—these check for safe chemicals and smoother downstream processing.

- Decoration methods: Favor water-based screen print, embroidery with matching fiber, or sublimation on polyester, keeping decoration areas limited and single-fiber when possible.

- Tolerances: Build in patterns and tolerances that allow for minor shrinkage and repair, extending usable life span.

For high-use sportswear: construction types (flatlock, coverstitch, ISO 301/401/504) and needle selection directly influence how easily a product can be repaired or eventually separated for recycling. Design teams and factories share these specs upfront to align on performance, repairability, and end-of-life success.

Balancing Performance, Durability, and Circularity

Circular design shouldn’t compromise sportswear performance. Durable materials—such as 240 gsm moisture-wicking polyester pique knits or 280 gsm organic cotton French terry—give gear a longer lifespan before entering recycling. Simple construction (e.g., minimal linings, double-stitched seams) makes both repair and recycling faster. Testing under standards like ISO 105-C06 (colorfastness) and AATCC 150 (dimensional stability) ensures stability through many wash cycles, one of the core metrics for eco-conscious buyers.

Even within strict durability goals, designers prioritize functionality: UV-resistant finishes, quick-dry coatings, and antimicrobial treatments can be added to mono-material knits using processes that do not block later recycling.

Measuring Success: Business Outcomes of Circular Sportswear

Making sportswear circular calls for investment in quality, lab work, and post-use handling. But it pays off:

- Higher customer retention: Repairable and recyclable gear builds brand loyalty.

- Lower long-term costs: Reduced waste and simpler recycling lower disposal fees and environmental taxes.

- Enhanced compliance: Meeting GOTS, OEKO-TEX, or BSCI standards wins business with eco-conscious clients.

- New revenue streams: Take-back and re-sale programs monetize repair and upcycled goods.

Reliable partners like Ninghow guide brands on everything from lab dips to final hangtag design, closing the gap between concept and market-ready circular sportswear. The right design choices deliver stronger, longer-lasting, more sustainable apparel—without trade-offs on performance or style.

Practical Checklist: Getting Started with Circular Sportswear Design

- Outline fiber strategy: Go mono-material whenever possible.

- Map every trim and accessory: Choose modular/snappable designs in compatible materials.

- Label for clarity and removal: Avoid adhesives and favor matching-fiber labels or prints.

- Engineer for easy repairs: Position accessible seams, standardized parts, and stress-point reinforcements.

- Build for collection: Use QR codes, batch labels, and educate end-users on take-back options.

- Test for recyclability: Coordinate lab work (OEKO-TEX, GOTS, AATCC) to validate material recovery ease.

- Choose manufacturers with proven sustainability workflows.

Expert note: “The single best way to improve recyclability and repair in sportswear is to keep designs simple and materials pure. Start every project by asking: can we disassemble this quickly, and will it create clean material streams for the next use?”

Frequently Asked Questions

What is circular sportswear design?

Circular sportswear design means creating athletic clothing with repair, reuse, and recycling in mind from the start, using strategies that support long garment life and easy recovery of materials at end-of-life.

Why are mono-materials important for sportswear recycling?

Mono-materials make recycling much simpler since they avoid mixing fibers that must be separated later; this boosts the speed, quality, and value of recovered materials.

How do modular trims help circular sportswear?

Modular trims can be detached or replaced easily, allowing for simple repair or removal during recycling without destroying the main garment fabric, which supports longevity and clean material recovery.

What role do take-back programs play in sustainability?

Take-back programs close the product loop by collecting used garments for repair, upcycling, or recycling, reducing landfill waste and helping brands meet sustainability goals.

How can clothing manufacturers support repairability?

Manufacturers can use accessible seams, standardized closures, reinforced stress points, and compatible trims to make sportswear easier to repair at both consumer and service center levels.

What are common challenges in circular sportswear design?

Key challenges include selecting mono-materials without compromising performance, designing for easy repair, managing diverse trim materials, and building efficient end-of-life collection systems.