Sampling Process for Apparel Brands: From Tech Pack to PPS

What Is the Apparel Sampling Process?

The sampling process is the step-by-step path from an idea to a production-ready product.

A strong sampling process helps you:

- Reduce revisions and wasted time

- Control fit and measurements

- Confirm fabric and trims early

- Lock print and embroidery details

- Make sure bulk production matches the approved sample

Key point: Sampling is not “one sample.” It is a sequence of samples, each with a clear purpose.

Why Sampling Gets Slow (and How to Fix It)

Sampling delays usually come from:

- A tech pack that is missing key details

- Unclear fit goals (too many opinions, no final decision)

- Too many changes at once

- Fabric or trim choices not confirmed early

- No clear approval rules (what is “pass” vs “revise”?)

You can fix most of this by setting clear inputs and clear decision points.

Step 1: Start with a Tech Pack That a Factory Can Follow

A tech pack is your product instruction manual. The best tech packs are simple, complete, and easy to read.

What a tech pack must include

- Style name and product type (polo, T-shirt, hoodie, shorts, etc.)

- Flat sketch or reference images

- Fabric requirements (type + weight + stretch, if needed)

- Construction details (key seams, stitch type, stress points)

- Measurement chart (with clear points of measure)

- Tolerances (how much variation is allowed)

- Decoration details (logo placement, size, colors)

- Labeling and packaging requirements

- Target quantity and size breakdown (for planning)

- Comments for fit intent (slim, regular, relaxed)

If you don’t have a full tech pack: Start with a “minimum tech pack” plus a reference sample.

Step 2: Choose the Right Sample Types (Not Just “Make a Sample”)

Common sample types (simple explanation)

- Purpose: Check the overall shape and construction

- Not perfect: Fabric and trims may be substitutes

- Use it to catch big issues early

- Purpose: Fix fit and measurements

- Use it to confirm key points (chest, body length, sleeve length, waist, etc.)

- Best practice: One person owns final fit decisions

- Purpose: Confirm grading across multiple sizes

- Helps prevent returns due to sizing problems

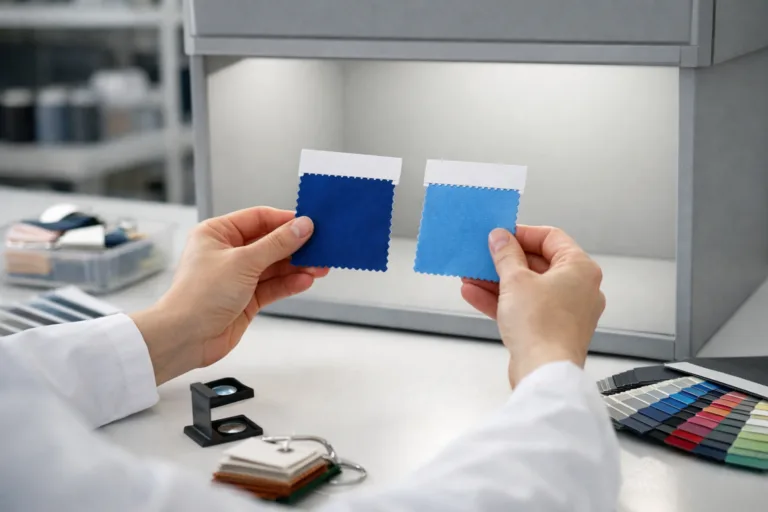

- Purpose: Confirm print, embroidery, and color matching

- Helps avoid misaligned logos or wrong colors in bulk

- Purpose: The final “bulk blueprint”

- Must match real fabric, trims, and workmanship

- Should be approved before mass production starts

Step 3: Confirm Fabric and Trims Early (This Saves Weeks)

What brands should confirm early

- Fabric handfeel and weight

- Stretch and recovery (for performance items)

- Shrinkage risk (wash test, if needed)

- Color standard (lab dip or bulk shade control)

- Trims: zippers, buttons, drawcords, elastic

- Labels and hangtags

Tip: If your fabric is custom-dyed, build extra time into your calendar.

Step 4: Use a Simple Review & Approval System

A simple sample approval workflow

- Factory sends sample with measurement sheet

- Brand checks fit + workmanship + decoration

- Brand sends feedback in one clear document

- Factory confirms changes before making the next sample

What good feedback looks like

- Clear and numbered comments

- Photos with arrows or circles

- Exact measurement corrections

- One final decision owner (not five people)

Step 5: Lock the “Golden Standard” Before PPS

Before PPS, you should confirm:

- Final measurements + tolerances

- Final fabric and trims

- Final print/embroidery placement and size

- Final labels and packaging

- Approved construction details

This “golden standard” is what the factory must follow for bulk.

Step 6: PPS Approval (The Step That Protects Bulk Production)

What PPS should prove

- Bulk fabric and trims are correct

- Measurements are within tolerance

- Workmanship matches your standard

- Decoration is correct and consistent

- Labels and packaging are correct

- Factory understands your exact requirements

Do not skip PPS if you are switching factories or launching a new style.

A Practical Sampling Timeline (Example)

Week 1–2: Tech pack + sourcing

- Finalize tech pack

- Confirm fabric and trims plan

Week 3–4: Proto / Fit sample

- Proto sample review

- Fit corrections

Week 5–6: Fit sample revision + size set (if needed)

- Confirm fit

- Confirm grading

Week 7–8: PPS

- Final materials

- Final workmanship

- Packaging and labels confirmed

Week 9+: Bulk production starts

- Inline QC checkpoints

- Weekly production updates

How to Speed Up Sampling (Without Losing Quality)

Here are the fastest, safest ways to speed up sampling:

- Send a complete tech pack (or a minimum version + reference sample)

- Limit first round options (fewer fabric choices, fewer colorways)

- Decide fit direction early (slim/regular/relaxed)

- Combine comments into one clear file

- Approve one thing at a time (fit first, then decoration)

Use a trial order plan to validate in real production conditions

Common Sampling Mistakes Brands Make

Avoid these and you will save weeks:

- Changing fit, fabric, and decoration all at once

- Approving fit without measuring

- Skipping size set for size-sensitive products

- Rushing to bulk without PPS

- Using unclear comments without photos or measurements

Letting too many people approve changes

How Ninghow Supports Faster, Clearer Sampling

Ninghow supports:

- Clear tech pack review before sampling starts

- Fast feedback loops with measurable changesn points

- Fit control with tolerance guidance

- PPS approval rules to protect bulk consistency

- Smooth handoff from sampling to production QC

If you want to test a new supplier, a low-risk trial order after PPS is a safe start.

Speed Up Sampling—Without Endless Revisions

Actions:

- Send Your Tech Pack (get a sampling timeline + clarification list)

- Request a PPS-First Plan (best for switching suppliers)

- Start a Development Trial (one style to prove speed + consistency)