Pillar Content:Clothing Manufacturing Process

Ensuring consistent clothing quality is critical for any fashion brand—whether you’re launching your first line or managing global wholesale operations. Poor quality can damage reputation and cause costly returns. At Ninghow, we follow strict, repeatable quality control (QC) standards to ensure every garment meets expectations. Here is a detailed checklist brands should follow to maintain quality.

Measurement Accuracy & Fit Testing

Accurate sizing is essential for customer satisfaction. Each product must align with the size spec sheet.

- Garment Measurements: Inspect chest, waist, sleeve length, inseam, etc., using calibrated tools.

- Tolerance Levels: Acceptable measurement variation (e.g., ±1 cm) should be predefined.

- Live Fit Testing: Try samples on live models or dress forms to verify comfort and proportions.

- Size Grading Review: Ensure consistent scaling between sizes (S, M, L, XL, etc.).

Consistency in sizing reduces returns and increases customer trust.

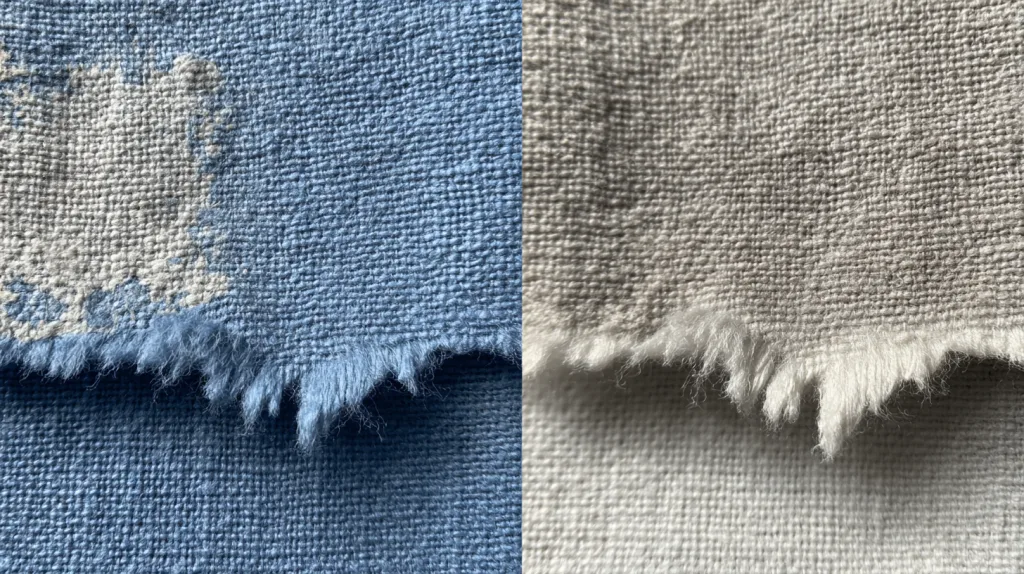

Fabric Quality (Shrinkage, Colorfastness, Pilling)

Fabric performance directly affects product value and longevity.

- Shrinkage Tests: Wash test samples according to care label and measure shrinkage rate.

- Colorfastness: Ensure dye doesn’t bleed or fade when exposed to light, water, or sweat.

- Pilling Resistance: Use Martindale or ICI methods to test fabric’s resistance to surface fuzz.

- Hand Feel Assessment: Subjective but important—fabric should feel appropriate for the product type.

Choose quality fabrics early to minimize downstream QC failures.

Stitching & Seams

Stitch quality affects strength, durability, and appearance.

- Seam Strength: Perform tensile strength testing on key stress areas.

- Stitch Density: Check for consistent stitch-per-inch based on the spec sheet.

- Thread Quality: Ensure threads match fabric type and don’t fray easily.

- Defect Inspection: Look for skipped stitches, loose threads, or uneven tension.

Inspect inside and outside of garments, as hidden flaws still impact durability.

Labeling & Compliance Standards

Labels are not just branding—they are legal requirements in many markets.

- Label Accuracy: Confirm correct size, fabric content, country of origin, care instructions.

- Placement: Labels should be sewn or heat-pressed in specified positions.

- Compliance Marks: Check for necessary certifications (e.g., CE, OEKO-TEX, CPSIA).

- Durability: Labels must withstand washing and wearing without fading or detaching.

Failing compliance checks can lead to customs delays or product recalls.

Packaging & Final Inspection

Presentation impacts customer experience and transport safety.

- Clean Finish: Garments should be lint-free, pressed, and neatly folded.

- Packaging Materials: Use appropriate polybags, hangtags, and inserts.

- Barcodes & Tags: Scan to confirm accuracy of SKU and pricing.

- Random QC Sampling: AQL (Acceptable Quality Level) sampling before shipment.

Final inspection ensures consistent product readiness across all units.

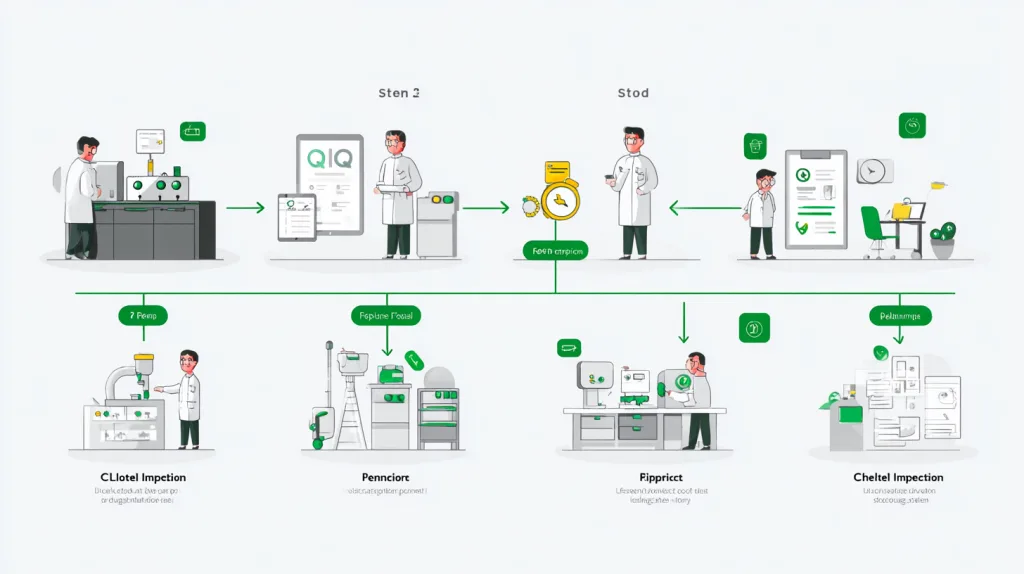

Ninghow’s Multi-Step QC Process

Ninghow takes quality control seriously, applying a proven multi-phase process for every batch:

- Incoming Fabric Check: Fabric rolls inspected before production.

- Inline QC Audits: Random checks during sewing and assembly.

- Pre-Final QC: Sample units checked before pressing/packing.

- Final Inspection: Batch reviewed against checklist + AQL standard.

- Client Reporting: QC summary with photos sent before shipment.

This workflow reduces risk and guarantees brand-level consistency.

CTA: Partner with Ninghow for Reliable QC

Quality issues cost money and hurt your brand. With Ninghow, you get a partner who understands every step of quality control in clothing production.

- Proven experience in OEM/ODM for global apparel brands

- No MOQ—flexible for startups and scaling labels

- Factory-direct QC with detailed inspection reports

- Support for sportswear, beachwear, and fashion items