What Does UPF 50 Mean?

UPF stands for Ultraviolet Protection Factor. A fabric rated UPF 50 allows only 1/50th (≈ 2%) of UV radiation (both UVA + UVB) to pass through to your skin — meaning it blocks about 98% of harmful rays. Any fabric labeled UPF 50+ is considered “excellent” protection.

This is often the highest UPF level used in clothing standards, especially for upf 50 clothing. It is the benchmark for top sun‐protective gear.

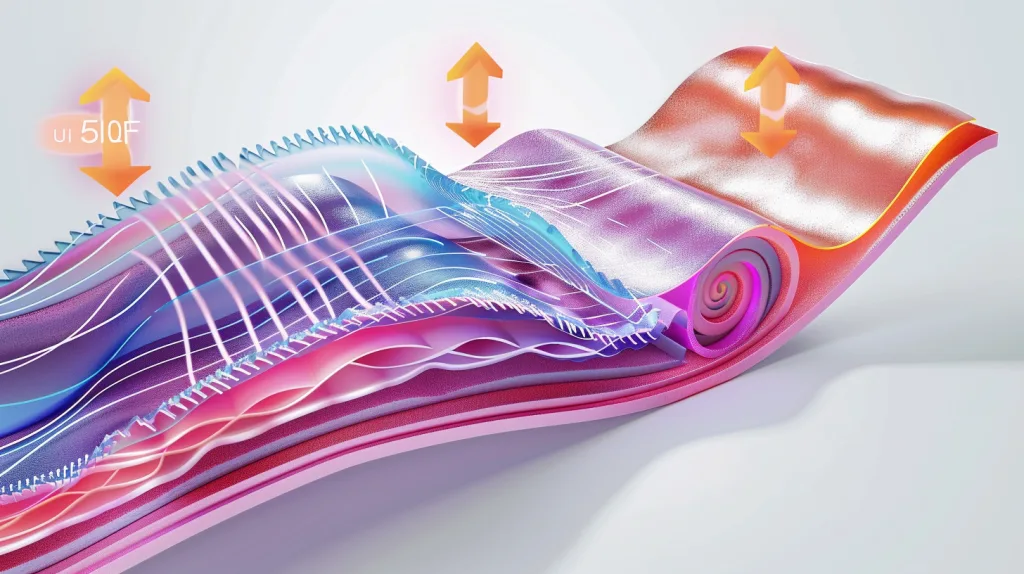

The Science Behind UPF 50+ Fabrics

UPF 50+ fabrics are engineered to block both UVA and UVB rays very effectively. The degree of protection depends on:

- Weave density / knit tightness: Fabrics with tighter weaves have fewer gaps for UV rays.

- Fiber type: Synthetic fibers (e.g. polyester, nylon) often perform better; natural fibers can also be UV‑protected via treatments.

- Color & dyes: Darker or UV‑absorbing dyes enhance protection; light colors usually offer less unless treated.

- Fabric weight & thickness: Heavier, thicker materials tend to block more UV, though with trade‑offs like breathability.

- Stretch / wetness / wear: All these can reduce UPF; testing often includes wet/dry and stretched conditions.

Best Fabric Types for UPF 50 Clothing

Choosing the right fabric is crucial for ensuring optimal protection. Consider exploring various options designed specifically for upf 50 clothing.

| Material | Advantages for UPF 50 | Considerations / Trade‑offs |

|---|---|---|

| Polyester / Nylon blends | Naturally high UV blockage; durable; good moisture‑wicking | Can be less breathable; might trap heat |

| Microfiber Synthetic Knits | Lightweight, quick‑dry; good for sports and active uses | Stretch may reduce protection; needs good finishing |

| Treated Natural Fibers | Comfortable feel; eco options available | Treatments can fade; needs dense weave |

| Bamboo, Modal | Soft, often cooler; eco appeal | Needs UV finish/tight weave for true UPF 50 |

Key Features of High‑Performance UPF 50 Garments

To get the most out of UPF 50 clothing, look for:

- Full coverage: long sleeves, high collars, longer hemlines

- Seam & stitching quality: avoid thin seams that let UV seep

- Breathability & moisture wicking: fabric that keeps wearer cool

- Durable finishes: make sure UPF holds up after washing and stretch

- Lightweight versions for hot climates; heavier fabrics for more coverage

How UPF 50 Clothing Compares to Sunscreen

- UPF 50 clothing offers reliable, continuous protection as it does not need reapplication, unlike sunscreen.

- Clothing can cover large areas (torso, arms, legs) often missed or under‑protected by sunscreen.

- Sunscreen effectiveness depends on amount and reapplication; UPF fabrics reduce human error.

- However, UPF clothing doesn’t protect exposed skin, so sunscreen is still needed in some areas.

UPF 50 Clothing for Outdoor Activities

- Swimming / Water sports: UPF 50 swimwear remains protective even when wet

- Hiking & Trekking: UV exposure is higher at altitude; durable UPF fabrics are key

- Running / Cycling: Lightweight, stretchable, sweat-wicking materials work best

- Boating & Fishing: Water reflects UV rays, increasing exposure — good coverage needed

- Outdoor Work: Uniforms and workwear should meet UPF 50 standards for daily safety

Custom UPF 50 Clothing Manufacturing: OEM & ODM Insights

If you want to build your own UPF 50 line, here are things to consider:

- Fabric selection: guarantee fabrics tested for UPF 50 or better (dry & wet, stretch included)

- Certifications: Use recognized standards (AATCC, EN / DIN, AS/NZS, UV STANDARD 801)

- Design tech packs: include coverage, seam placement, color, fit

- MOQ & sampling: begin with samples to test wear + real results

- Finishing & labeling: include UPF rating, care info, fiber content, origin info

Choosing the Right UPF 50 Styles for Your Brand

- Everyday casual: T-shirts, hoodies with breathable UPF 50 fabrics

- Activewear: rash guards, compression leggings, UV tops

- Kidswear: soft, stretchy UPF 50 fabrics with playful prints

- Resortwear: stylish dresses, kaftans, wraps with UV-blocking materials

- Workwear: uniforms with long-term durability + UV safety

MOQ and Production Flexibility for UPF 50 Apparel

- UPF fabrics sometimes have higher MOQs due to treatment processes

- Ninghow supports low-MOQ for startups using in-stock UPF 50 fabrics

- Begin with samples and small runs, then scale based on market response

- Production lead time: usually 4–6 weeks after sample approval

UPF 50 Certification and Testing Standards

Recognized global UPF standards:

- AATCC TM-183 (USA)

- EN 13758-1 (Europe)

- AS/NZS 4399 (Australia/New Zealand)

- UV STANDARD 801 (Global, strictest — includes stretch, wear, wet testing)

Always test garments with third-party labs. Use proper labeling to ensure legal compliance and build consumer trust.

Packaging and Labeling for UPF Clothing

- Label clearly: include UPF value, wash instructions, fiber content, country of origin

- Use anti-UV tags for marketing and information

- Sustainable packaging: biodegradable bags, recycled tags, QR codes with care info

Trends in UPF 50 Fashion and Resort Wear

- Athleisure UV wear: Performance fabrics in trendy silhouettes

- Eco UPF lines: Made with recycled polyester or bamboo + plant-based dyes

- Travel-friendly designs: wrinkle-resistant, compact, stylish and sun-safe

- Dual-purpose items: Swim-to-street dresses, UV shawls, hooded rash vests

Global Market Demand for UPF Clothing

- Global sun protective clothing market projected to grow to $14B+ by 2030

- USA, Australia, Middle East, Southeast Asia have highest demand

- Medical professionals and dermatologists increasingly recommend UPF wear

- UPF awareness is growing across all demographics

Sustainability and UPF Clothing: What to Consider

- Use of recycled or biodegradable fibers like rPET or bamboo

- Non-toxic UV finishing processes (OEKO-TEX / Bluesign certified)

- Reduced water and energy usage in production

- Fair-wage, ethical labor supply chains

Case Studies: UPF 50+ Brands Powered by Ninghow

- Brand A – Swimwear Startup: Collaborated with Ninghow to develop 4 SKUs of UPF 50 rash guards and swim leggings. Lab-tested for UPF after 20 washes. MOQ: 300 pcs/style. Delivered in 45 days.

- Brand B – Outdoor Lifestyle Label: Sourced quick-dry UPF 50 fabrics for hikers. Added ventilation zones and odor-control features. Reorders doubled after first season.

- Brand C – Resortwear Brand: Used sustainable modal + plant dyes for stylish UPF dresses. Combined with recycled packaging and QR-based digital tags.

Starting Your Own UPF 50 Clothing Line

- Define your niche: beachwear, sport, resort, kids, workwear?

- Select fabric and style range: balance coverage, breathability, cost

- Build prototypes and test for UPF + consumer feedback

- Finalize MOQ, labeling, branding

- Choose a factory like Ninghow for expert OEM/ODM manufacturing

- Launch with educational messaging about UV protection

- Scale through direct-to-consumer or wholesale models

FAQ

Q1: How long does UPF 50 last?

A: It depends on the fabric and finish. Some UPF ratings last through 20–40 washes; others are permanent.

Q2: Can I request sustainable UPF 50 materials?

A: Yes. Ninghow offers bamboo, recycled polyester, eco-packaging, and natural dye options.

Q3: Is UPF 50 legally required on the label?

A: It’s not required globally but highly recommended. Lab-tested certification builds trust.

Q4: What is a good MOQ for launching?

A: 200–300 pieces per style is common. Some base fabrics allow lower MOQs.

Q5: Does UPF 50 work when the fabric is wet?

A: Some fabrics maintain full protection wet; others reduce. Always test for “wet UPF” if needed.

Conclusion

UPF 50 clothing is one of the best tools for reliable sun protection — blocking ≈98% of harmful UV rays when done correctly. For brands, emphasizing quality materials, proper testing & certification, functional design, and consumer education is key. With consumer awareness increasing, there’s real opportunity in offering UPF 50+ apparel that blends protection, comfort, style, and sustainability.