Sublimation Printing for Team Jerseys: A Manufacturer’s Guide

Sublimation printing has become the gold standard for team jerseys, offering vibrant color, lightweight performance, and limitless design flexibility. Brands, clubs, and sportswear labels rely on this method to stand out on the field while maintaining comfort and durability. As a trusted sublimation jerseys manufacturer, understanding each manufacturing stage is critical to ensuring consistent quality, cost control, and customer satisfaction. Below, we dive deep into all aspects—from fabric compatibility and panel design to colorfastness and efficient workflows.

Why Sublimation Printing Is Preferred for Team Jerseys

Sublimation printing uses heat to bond specialized inks directly into polyester fibers. This technique creates vivid, long-lasting graphics that never peel or crack. Jerseys retain their soft handfeel, remain breathable, and withstand washing and play. For teams, the result is consistent branding and colors for every player—season after season.

- Unlimited colors and gradients (no extra cost per color)

- Photographic-quality designs, names, and numbers

- Prints do not affect fabric breathability or texture

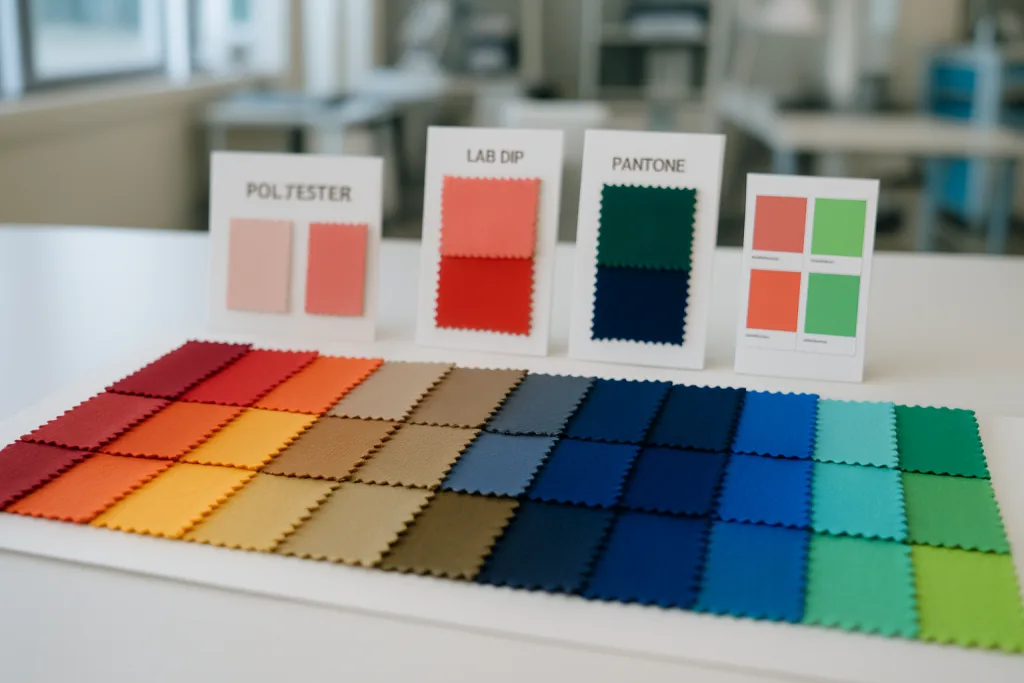

- Exact Pantone color matching possible after controlled lab dips

For team orders, sublimation unlocks late-stage customization, lower order minimums, and rapid turnarounds. Let’s examine the key steps and technical factors every serious manufacturer must control.

Fabric Compatibility: Foundation for Sublimation Success

Sublimation only bonds with synthetic fibers, primarily polyester. Cotton or blended fabrics yield faded or washed-out results, as natural fibers cannot properly open up to receive sublimation dyes. View more sportswear fabric guides.

Best Fabrics for Sublimation Jerseys

| Fabric Type | GSM Range | Main Properties | Best Use |

|---|---|---|---|

| 100% Polyester (Warp Knit) | 150–180 gsm | Lightweight, smooth, color brilliance | Soccer, cycling, rugby jerseys |

| Polyester Interlock | 140–170 gsm | Double-knit, heavier drape, snag-resistance | Basketball, baseball, esports tops |

| Poly Spandex Blend (90/10) | 130–180 gsm | Added stretch, form-fitting | Compression shirts, fitted uniforms |

| Microfiber Poly (Micro Mesh) | 120–160 gsm | Maximum airflow, moisture-wicking | Training, warm-weather kits |

Key Technical Checks

- Pre-treatment: Ensure fabric is free of oils, finishes, or contaminants that block dye uptake. Choose sublimation-ready stock when possible.

- Whiteness: Opt for optical bright white for the most vivid colors—as dyes merge with base shade.

- Supplex, Recycled Polyester (rPET): Both can be sublimated, but check for pre-tested strike-offs to confirm print fastness and depth.

Panel Layout: Optimizing Patterns and Print Placement

With jersey sublimation, intricate designs are printed on flat fabric panels before assembly. This approach enables edge-to-edge artwork, precise graphics alignment, and optimal use of material. However, it demands careful technical planning.

Developing Tech Packs Early

Start with a detailed tech pack—complete with graded size sets, marker guides, and seam allowances. Indicate panel orientation and any logo/graphic placement instructions. Supply vector files (.AI/.EPS) for best results. Ninghow’s pattern team verifies markers, grainlines, and scoring for consistent sizing and construction quality across B2B runs.

Best Practices for Panel Printing

- Allow 3–5mm bleed—for full-frame coverage and tolerance on cut lines.

- Align stripes and graphics using precise notches and print alignment marks on each panel.

- Position numbers/names to maximize readability, accounting for seam lines and post-sew stretch.

Fabric Relaxation and Cutting

After sublimation, let panels rest for 12–24 hours before auto-cutting. This ensures fabric shrinks to final dimensions, reducing size variation in finished jerseys. Use auto-cutters or well-marked manual tables for precision, and check grainline to maintain stretch and drape properties.

Color Depth, Fastness & Bulk Consistency

Exceptional color is the hallmark of top-tier sublimation jerseys. Vivid shades, deep blacks, and accurate logos reinforce team identity and brand quality goals.

Steps to Achieve Deep, Stable Colors

- Color Lab Dips: Pre-approve fabric whitness and base tone. Run test prints with Pantone comparisons before proceeding to bulk.

- Strike-Off Sampling: Print a strike-off for every new design, panel, or fabric type. Visually match color under standardized D65 lighting.

- Bulk Color Approval: Create a shade band of approved panels. Any batch outside ±1.5 Delta E (color variation) is flagged for correction.

- Pigment Load: Adjust ink and heat press dwell to set color depth without oversaturation or bleed-through.

Testing for Colorfastness

Use ISO 105-C06 and AATCC 61 wash tests to check color retention after repeated laundering. Good results show no visible shade loss or migration after 5+ wash/dry cycles. Conduct rub (crocking) and light fastness checks for additional peace of mind.

MOQ and Production Lead Times for Sublimation Jerseys

Sublimation unlocks lower minimum order quantities (MOQs) compared to traditional printing techniques, as there’s no need to burn color screens. However, true efficiency comes from organized workflows and batch scheduling.

MOQ Best Practices

- Standard MOQs: 30–50 pieces per design or size set. Lower runs (10–20) may incur higher setup costs due to fabric and press calibration.

- Bulk Savings: Group sizes and styles together for cost-effective yardage and panel printing. Larger orders (200+ units) allow fine-tuned panel grouping and reduced fabric waste.

Lead Time Planning

- Lab Dip & Prepress Setup: 3–5 days for first-time orders, faster for reorders or previously approved fabrics.

- Bulk Printing & Cutting: 5–7 days for up to 500 pieces, with split lots for larger runs.

- Sewing & Finishing: 4–8 days, depending on jersey complexity, added trims, and embellishments like embroidery or heat transfers.

- Final QC & Packing: 1–2 days for inline and endline checks, spec measurements, and export packing.

In total, expect 2–3 weeks from sample approval to finished shipment. Ninghow achieves even faster turnarounds for established customers by maintaining pre-tested fabric stocks and lean workflow management.

Quality Control: Print, Construction, and Performance

Quality assurance begins well before final sewing. Every sublimation jerseys manufacturer should apply rigorous checks at critical points to prevent costly mistakes and rework.

QC Points in Sublimation Workflow

- Prepress Inspection: Review print files, panel artwork alignment, and bleed settings before printing.

- Inline Color & Size QC: Check color consistency, registration, and panel size specs after sublimation and before cutting.

- Sewing Checks: Inspect stitch type (ISO 401/504 for seams, 602 coverstitch for hems), bar tacks at stress points, rib collar attachment if applicable.

- Endline QC: Spec table measurement, print crispness, wash & dimensional stability (AATCC 135), seam strength (ASTM D1683), and skew/pucker checks.

- Needle Detection: Where access-controlled programs require it, run finished goods through metal detectors to prevent accidents from broken needles.

Certifications such as OEKO-TEX STANDARD 100 and GOTS offer additional assurance—especially when producing jerseys for major leagues, schools, or retail programs.

Effective Prepress Checklist for Sublimation Jerseys

A robust prepress process prevents color errors and misaligned graphics while safeguarding fast turnarounds. Below is a step-by-step checklist for any high-level sublimation jerseys manufacturer:

- Verify fabric lot and roll code match lab dip approval

- Print and check strike-off for color, registration, and handfeel

- Export print files as CMYK with 300 DPI minimum resolution, bleed, and double-check vector graphics

- Double-check pattern panel dimensions/markers against approved tech pack

- Align print orientation to garment’s grainline for best stretch and visual effect

- Sign off bulk print sheet before mass run

Expert Tip: Always keep a retained library of approved shade bands, strike-offs, and bulk print panels for future reference and client reorders.

Sublimation Jerseys Manufacturer: What Sets Industry Leaders Apart?

Market leaders go beyond equipment and ink. They deliver pinpoint fit, color accuracy, print durability, and seamless service. Firms like Ninghow offer:

- Consistent fit blocks and graded sizing for every program

- Fine-tuned panel nesting to reduce fabric waste and costs

- Emerging fabric options (such as recycled rPET and wicking finishes)

- Compliance with global safety and sustainability standards (REACH, OEKO-TEX, BSCI/WRAP, and more)

- Clear, proactive communication—PP samples and TOPs before production release

- Flexible MOQ for clubs, brand launches, and major retail rollouts

Professional manufacturers act as silent partners, supporting OEM/ODM clients with process transparency and repeatable quality from first sample to repeat orders.

Finishing Touches: Beyond Printing

Often, the difference between good and great sublimation jerseys comes down to finishing. While sublimation handles base colors and graphics, add-ons complete the athlete experience.

Key Finishing Options

- Embroidery: Team crests or sponsor logos placed pre-assembly or on finished panels for raised, tactile detail.

- Heat Transfers: Player names, numbers, or special event badges for short-run customization.

- Moisture-Wicking Finish: Post-sublimation chemical treatment or yarn technology to boost sweat control.

- Anti-odor & UV Finish: For sports, outdoor, or youth programs that demand comfort and extended wear.

- Durable sewing: Double-needle coverstitch on hems, flash seam tape for irritation-free inside construction.

Choose packaging to match your market: size-ratio polybags, custom hangtags, retail folding, and clear carton labeling. International shipments should comply with Incoterms and feature full barcoding for inventory control.

Applications: Where Sublimation Jerseys Excel

Sublimation jerseys are the standard in sports, but the technology is also popular for:

- Corporate teamwear and promotional events

- Esports uniforms and branded gaming apparel

- Resort, holiday, and destination kits for group travel

- Charity runs, school leagues, summer camps

The flexibility of runs, turnaround, and design options means even smaller brands or clubs can access pro-level results. Whether for a local club, a national league, or global brand activations, the right manufacturer turns creative concepts into reality—on time and on budget.

Summary: Choosing Your Sublimation Jerseys Manufacturer

Success with sublimation printing for team jerseys is built on detail and reliability: match the right polyester fabric to your sport, plan panels for perfect placement, and maintain strict QC at every turn. Factor in lead times, batch size, and finishing needs from the start. A trustworthy partner like Ninghow supplies fit blocks, repeatable color, and expert prepress—all with a commitment to quality and sustainability for any sporting or promotional program.

Frequently Asked Questions

What fabrics are best for sublimation jerseys?

100% polyester fabrics are ideal, especially warp knit, interlock, and micro-mesh styles in 140–180 gsm for lightweight, vibrant results. Cotton or blends are not suitable.

How do you ensure consistent color across bulk orders?

Manufacturers conduct lab dips, strike-off sampling, and create approved shade bands. Color is checked to within ±1.5 Delta E between batches using controlled lighting.

Are there minimum order quantities (MOQs) for sublimation jerseys?

Typical MOQs are 30–50 pieces per style, but some factories offer lower runs with adjusted costs. Grouping styles and sizes helps minimize fabric waste and unit prices.

How long does sublimation jersey production take?

From prepress approval to finished garments, lead times are usually 2–3 weeks. This varies by order size, fabric readiness, and added details like embroidery or special packaging.

What colorfastness standards apply to sublimated jerseys?

Key tests include ISO 105-C06 and AATCC 61 for wash fastness. Jerseys should maintain color and vibrancy after repeated laundering and wear.

What is included in a prepress checklist for team jerseys?

Checks cover fabric matching, print file setup, pattern marker alignment, bleed, color and registration checks on strike-offs, and final sign-off before bulk print runs.