Pillar Content:Clothing Manufacturing Process

Sportswear needs to look great, feel comfortable, and stay vibrant wash after wash. Choosing the right printing method—screen printing vs sublimation—can make a big difference. Let’s explore both, compare them clearly, and help you decide which one is best for your needs.

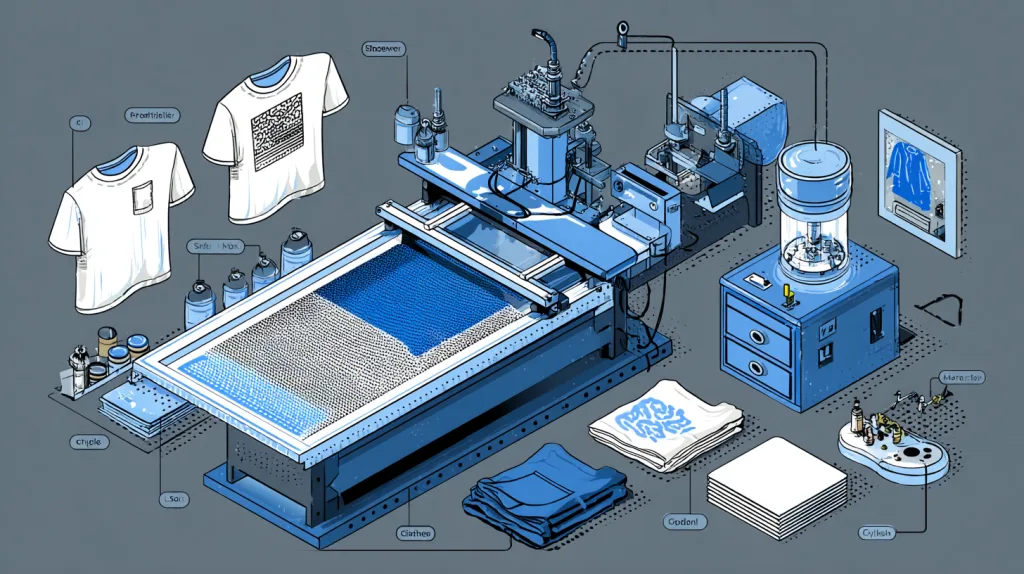

What is Screen Printing?

Definition and Process

Screen printing is a traditional method where ink is pushed through a stencil (called a screen) onto fabric. Each color needs its own screen, and the ink sits on top of the fabric in thick layers. It’s like stamping the design on—bold, bright, and strong.

Materials & Inks Used

Screen printing uses plastisol or water-based inks. Plastisol is thick, sits on the surface, and works well on many fabrics. Water-based inks soak in more, giving a softer feel, but may fade sooner if not cured correctly.

Durability & Color Quality

This method delivers strong, opaque colors. It works well on dark and light fabrics alike. The ink layer resists cracking and lasts long, especially after proper curing (heating). Designs often feel a bit raised and textured.

What is Sublimation Printing?

Definition and Process

Sublimation printing uses heat to transfer dye into polyester or similar fabrics. The ink turns into gas and embeds directly into the fibers. This means the design becomes part of the fabric, not just on top.

Materials & Inks Used

Sublimation needs special dyes and polyester-based fabrics. It works best on white or light-colored polyester. The ink penetrates the textile, so you don’t see or feel any extra layer of print.

Durability & Color Quality

Colors are vibrant and long-lasting because they fuse with the fibers. Washes don’t fade the print, and there’s no cracking or peeling. The print stays smooth and soft to the touch.

Pros & Cons of Screen Printing

Advantages

- Bold, vibrant colors: Great for dark fabrics or bold designs.

- Cost-effective for large runs: Unit cost drops as you print more.

- Versatile across fabrics: Works well on cotton, blends, and synthetics.

- Heavy-duty durability: Stands up to frequent washing if cured well.

Limitations

- Setup costs: Creating screens can be expensive, especially for small runs.

- Limited detail: Fine gradients or photographic images are harder to reproduce.

- Raised feel: Not ideal for ultra-light or stretchy sportswear where you want a smooth feel.

- Multiple colors add complexity: Each new color needs a new screen, raising time and cost.

Pros & Cons of Sublimation Printing

Advantages

- Unlimited color capability: Ideal for full-color, photographic, or gradient designs.

- Soft, breathable prints: Since dye is inside the fabric, there’s no extra texture.

- Durable and wash-resistant: Colors stay bright through many washes.

- Lightweight feel: Perfect for high-performance sportswear aiming for breathability.

Limitations

- Fabric restriction: Only works on polyester or poly-blends with high polyester content.

- Light backgrounds only: Doesn’t show well on dark fabrics.

- Higher per-unit cost for small orders: Less cost-effective for short runs compared to screen printing.

- Special equipment needed: Requires heat presses and dye-sublimation printers.

Cost Comparison

Upfront Setup Costs

- Screen Printing: You pay for each color’s screen. Good for large batches—startup cost is justified.

- Sublimation: No screens needed, but printers and heat presses cost more upfront. Better for smaller runs, but initial gear is pricier.

Cost per Unit

- Screen Printing: Lower cost per unit with higher quantities. Great for bulk orders.

- Sublimation: More consistent cost per unit regardless of volume. Full-color prints are easier but cost more per piece.

Volume Considerations

- Big batches: Screen printing wins if you want just a few colors.

- Small or custom runs: Sublimation shines—detailed, colorful, and flexible, even for small orders.

Best Use Cases for Each Technique

Ideal Scenarios for Screen Printing

- Bold, single-color or limited-color designs on cotton t-shirts, cotton-blend hoodies, or heavyweight jerseys.

- Large team uniforms or promotional sportswear where volume justifies screen costs.

- Wanting thick, crisp graphics.

Ideal Scenarios for Sublimation Printing

- Full-color, photographic, or gradient-heavy designs on polyester sportswear—cycling jerseys, soccer kits, running tops.

- Lightweight, breathable garments—when feeling of print matters.

- Custom, small batch orders with complex artwork.

Choosing Based on Fabric & Design

- Cotton or dark fabric? → Screen printing gives richness and stability.

- Polyester, light background, complex artwork? → Sublimation gives lifelike, smooth prints that last.

CTA: Get Expert Printing Solutions with Ninghow

Looking for high-quality customization? At Ninghow, we specialize in both screen printing and sublimation printing tailored for sportswear. Whether you need bold, durable prints or soft, complex designs, we offer:

- No Minimum Order Quantity (No MOQ)

- OEM/ODM capabilities for branded manufacturing

- Sportswear, beachwear, and business apparel options

- International wholesale with fast turnaround

Ready to get started? Get expert printing solutions with Ninghow now, and let us bring your designs to life!

FAQ

1. What is the usual turnaround time for screen printing vs sublimation?

- Screen Printing: Typically takes 5–10 business days, depending on artwork complexity and colors. Screens need prep, curing, and quality checks.

- Sublimation Printing: Faster setup—around 3–7 business days. Great for quick-turn custom orders.

2. Is there a minimum order quantity (MOQ) for each?

- Screen Printing: Often has an MOQ to make screen setup cost-effective—usually 50–100 pieces per design/color.

- Sublimation Printing: Lower or no MOQ—small runs (even 1 piece) can be done affordably with digital setup.

3. Which fabrics work best for each technique?

- Screen Printing: Cotton, cotton blends, polyester, even performance knits.

- Sublimation Printing: Only polyester or high-polyester blends, ideally light-colored or white for best color results.

4. How long do colors last after washing?

- Screen Printing: With proper curing and quality inks, prints last through 50+ washes without significant fading.

- Sublimation Printing: Extremely durable—the print is inside the fiber, so it resists fading, cracking, or peeling even after many washes.

5. Can I mix both methods in one order?

Yes! You can use screen printing for certain elements (like team logos) and sublimation for full-color backgrounds or patterns. Hybrid printing gives you flexibility, though it may raise cost and setup complexity slightly.

6. Are there eco friendly ink or dye options?

- Screen Printing: Yes—water-based, eco friendly inks that use less energy and produce less waste are available.

- Sublimation: Some dye sublimation inks are formulated to be low-VOC and eco-conscious, especially those paired with polyester fabrics made from recycled materials.

Conclusion

Both screen printing and sublimation printing bring unique strengths to sportswear production. Screen printing excels in durability, boldness, and cost-efficiency for large, simple-color runs. Sublimation shines with vivid, full-color designs and a smooth, breathable feel—especially on polyester gear.

When choosing:

- For cotton or dark fabrics with simple or bold designs, go with screen printing.

- For light polyester garments with complex, vibrant artwork, choose sublimation.

Ninghow offers expert solutions for both methods, with flexible OEM/ODM, no MOQ, and international wholesale services tailored to your sportswear needs.