Your Guide to Reflective & High-Visibility Solutions for Night Running

Night running brings freedom and focus, but also real risks. Low light means less visibility for runners near traffic, in parks, or along city streets. This makes reflective sportswear essential. Quality visibility gear can mean the difference between a safe jog and a close call. Today, apparel engineering offers many ways to boost visibility—combining science, style, and durable design. Let’s break down the modern advances, best practices, and design ideas in reflective and high-visibility solutions for night running.

Why Reflective Sportswear Matters for Night Runners

Standard running wear fades into darkness. Vehicle headlights may catch a simple stripe, but today’s reflective sportswear goes far beyond the basics. Retro-reflective trims, specialized heat transfers, and engineered piping direct light back to its source, making the wearer pop against a dim background. Runners using these products get spotted sooner—and stay safer.

Core Retro-Reflective Technologies Explained

Understanding how retro-reflection works allows designers and buyers to make better choices. In night running apparel, the most common retro-reflective methods include reflective trims, heat transfer films, and sewn piping.

Retro-Reflective Trims

These trims use micro-glass beads or prismatic films to bounce light directly back. When placed on motion-heavy zones (like legs or arms), they boost a runner’s visibility by reflecting car headlights efficiently.

Heat Transfer Reflective Films

Heat transfer films apply reflective elements through pressure and heat. This method allows flexible, stretch-friendly areas—ideal for sleek silhouettes or sportswear using elastane. High-quality transfers from brands like Ninghow balance reflectivity with wash durability.

Reflective Piping

Reflective piping outlines seams or panels. This adds subtle but powerful lines of illumination. It is often implemented along raglan sleeves, hems, or side panels for both style and safety.

Key Properties for Night Running

- Brightness: Measured in candela/lux; higher numbers mean more visibility.

- Angle of Return: Retro-reflection works best facing light sources directly, but some trims boast wide-angle performance.

- Durability: Proper attachment and finishing help trims last through heavy use and cleaning cycles.

Reflective & High-Visibility Solutions for Night Running

The challenge: Create gear that not only looks sharp in daylight but delivers proven safety after dark. Let’s explore leading apparel solutions and see how they perform for real runners:

Strategic Placement for Maximum Visibility

Placement is everything. Motion attracts the eye. Smart brands use reflective elements on:

- Lower legs (calves and ankles)

- Wrists and hands

- Shoulders, elbows, and outer sleeves

- Back yoke and central spine zones

- Side seams and cross-chest lines

Full 360-degree visibility means reflectives are visible from behind and the sides, not just the front.

Design Best Practices for Night Running Gear

Activewear leaders—including Ninghow—follow strict design and production workflows for reflective apparel:

- Tech Pack Detailing: Clear artwork, trim width, and placement notes to control consistency at bulk scale.

- Fabric Selection: Choose base knits (single jersey, interlock, French terry—typ. 160–240 gsm) that hold reflective elements without puckering.

- Pre-Production Sampling: Lab dips, strike-offs, and placement tests confirm adherence to visibility standards.

- Quality Assurance: Inline and endline checks verify reflectivity, wash durability, and seam placement.

- Wash/Weather Testing: Simulated laundering and abrasion confirm that reflectives keep working long term (ISO 6330, AATCC 61/8; see ASTM D4956 for reflectivity standards).

Avoid placing reflective trims only on large, flat surfaces. Dynamic and angular placement (especially in zones that move) increases visual impact under headlights or bike lamps.

Retro-Reflective Types and Comparisons

| Method | Fabric/Finish | Properties | Best Use |

|---|---|---|---|

| Retro-reflective tape | Micro-glass bead film | High candela/lux, moderate flexibility | Jackets, vests, pants |

| Heat transfer film | Polyester, elastane blends | Flexible, lightweight, moisture resistant | T-shirts, base layers, tights |

| Piping/cording | Poly/cotton core with reflective sheath | Decorative, outlines shape, durable | Hoodies, hats, sports shirts |

| Embroidered reflective thread | Poly core filament with glass bead wrap | Custom logos, low-contrast details | Caps, badges, custom trims |

Real-World Wash Durability: What to Expect

High-visibility trims must hold up against repeated use. Reflective elements from trusted suppliers withstand at least 20–30 home laundering cycles at 40°C without significant loss of reflectivity (test per ISO 20471). For bulk programs, always demand lab reports and check pre-production samples for pilling, delamination, or discoloration.

Certifications and Compliance for High-Visibility Apparel

Night running products should meet the latest safety standards. Look for compliance with:

- EN20471:2013 +A1:2016 (EU)—high-visibility warning clothing

- ANSI/ISEA 107-2020 (US)—reflective safety apparel

- OEKO-TEX® STANDARD 100—ensures reflectives, dyes, and finishes pass safety thresholds

- Proposition 65/CPSIA—pertaining to trims and inks for US distribution

Certifications protect runners, teams, and brands alike. Responsible manufacturers, such as Ninghow, supply compliance certificates with all B2B orders.

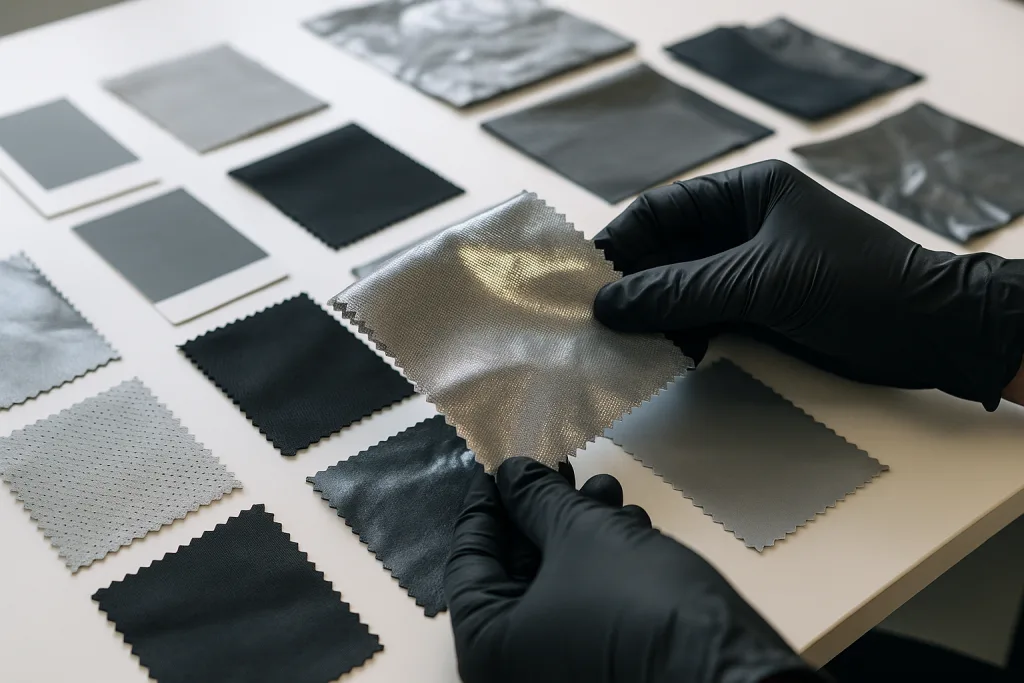

Gallery: Design Inspirations for Night Running

Whether you want eye-catching style or low-key visibility, today’s reflective sportswear offers endless creative options:

- Geometric/angled reflective zones across chest and backs

- Micro-piping along raglan sleeves—contrasting or same color for subtlety

- Vertical reflective tape extending from collar to lower hem

- Logos and motifs using reflective embroidery thread

- Laser-cut mesh panels with integrated reflective insets

Strategic use of Pantone shade bands ensures vibrant day color and pinpoint accuracy for logos or branding, even after repeated washing and wear. Colorfastness and shade control matter for longevity—checked with lab dips and bulk approval samples.

Behind the Scenes: Quality Manufacturing for Reflective Sportswear

Building high-visibility night running apparel isn’t just about adding shiny surfaces. It demands strict process control at every step. Leading B2B suppliers like Ninghow maintain fit consistency, stitch integrity, and precise placement for trims and heat transfers.

Fabric Choices & Construction Methods

Most reflective sportswear uses lightweight polyester or blended knits (with options for 160–240 gsm). If softness is key, organic cotton or combed ringspun blends add comfort—but they must suit the chosen reflective method. French terry or fleece (280–360 gsm) work for hoodies or cool-weather gear.

Pattern + Cutting for Consistency

- Precision markers for minimizing waste on placement trims

- Graded size sets and digital markers control alignment

- Fabric relaxation before cutting helps reflective trims sit flat

Sewing & Application Techniques

Reflective trims are sewn using strong stitches (ISO 301 lockstitch or ISO 504 double chainstitch). Heat transfers require calibrated presses—temperature, time, and pressure tuned to each fabric blend. Notches and alignment guides help prevent skewing or stretching during assembly.

Decoration and Logo Application

Reflective screenprints, embroidery, or laser-cut patterns turn logos into safety features. Durable water-based or plastisol inks pass REACH and CPSIA for non-toxicity. Embroidery uses specialty thread for 3D puff or flat stitch—tested for washing and abrasion.

Quality & Compliance: What Sets Premium Gear Apart

- Inline and endline QC for trim placement, puckering, and wash tests

- Spec measurement tables (±1 cm) for all trim and logo positions

- Batch color/shade control—bulk vs. approved lab dips

- Packing in size ratio bundles, with individual UPC barcode and care labels (ISO 3758)

Packaging & Export Readiness

Commercial buyers need reliable delivery. Finished sportswear is folded, polybagged, and shipped in custom cartons—carton marks, ratio packs, and QR/barcode integration included. Incoterms (FOB/CIF/DDP) set buyer expectations for cost and delivery risk. Pre-shipment AQL (usually 2.5/4.0 per ANSI Z1.4) and TOP sample approval round out quality control.

Ordering Reflective Sportswear: Smart Questions to Ask

When choosing a reflective sportswear partner, apparel buyers should address:

- Reflectivity (c/lux) ratings and durability/wash test reports

- Sample and strike-off review for every trim or print method

- Compliance documentation: EN20471, ANSI/ISEA 107, OEKO-TEX®

- MOQ, lead time, packaging options, and aftersales support

- Customization—can they match brands’ color, size, or placement needs?

A trusted provider like Ninghow clothing supplies tech pack guidance, quality manufacturing, and technical support throughout the ordering and production process.

Trends: The Future of High-Visibility Night Running Apparel

Leading brands continue to innovate:

- Laser-tuned reflectivity: Variable reflectives that adapt to ambient light

- Eco-friendly trims: Recycled polyester (rPET)-based tapes and films

- Smart textiles: Reflectives integrated with moisture sensing, UV indicators, or even LED strips

- No-sew bonding: Seamless reflective taping for better comfort, less chafing

Sustainability gains ground, with increased use of GOTS-certified organic cotton bases and recycled trims—without compromising safety standards. Rapid tech development keeps runners safer, longer, and in more style than ever before.

Reflective & High-Visibility Solutions for Night Running: Design Summary

The best night running gear blends standout performance with technical detail. Premium reflective sportswear gives athletes, teams, and brands an edge—boosting both safety and credibility. That advantage means attention to detail at every stage: strategic placement, compliant materials, rigorous testing, and specialist manufacturing like Ninghow delivers. Night running should be bold, not risky. With these advanced solutions and best practices, runners can move confidently—seen, safe, and unstoppable.

Frequently Asked Questions

How often should reflective sportswear be replaced for maximum safety?

Most reflective sportswear maintains effective visibility for 20–30 wash cycles if cared for per instruction; replace if brightness fades, elements peel, or trims crack.

Where are the best places to add reflective trims on night running gear?

High-motion zones—calves, wrists, shoulders, elbows, and the back yoke—are best for reflective trims, maximizing detection from multiple angles in low light.

Do reflective elements lose effectiveness after washing?

Quality trims and transfers from reputable suppliers withstand repeated washing, but improper care or harsh detergents can reduce reflectivity over time.

Are there international standards for reflective sportswear?

Yes, key standards include EN20471 (Europe) and ANSI/ISEA 107 (US). Look for OEKO-TEX® certification to ensure trims and finishes are also safe for skin.

What fabric types work best with heat-applied reflective transfers?

Polyester, elastane blends, and technical single jersey/fleece perform well; fabrics must withstand heat without distortion or color shift for best results.

Can logos or letters be made reflective on running apparel?

Yes, logos and names can be rendered in reflective ink, heat transfer, or embroidery, merging brand visibility with the safety benefits of high-visibility features.