Pillar Content: High Capacity Clothing Manufacturer Guide

Managing large-scale apparel production isn’t just about having the machines and manpower—it’s about having a system. At Ninghow, our ability to consistently deliver over 100,000 units each month doesn’t come by chance. It’s the result of well-designed workflows, precise coordination, and a factory culture rooted in efficiency.

In this article, we take you behind the scenes of our clothing factory output strategy. Whether you’re a growing brand, sports team, or startup exploring large volume production, you’ll discover how we manage complexity while maintaining quality and flexibility.

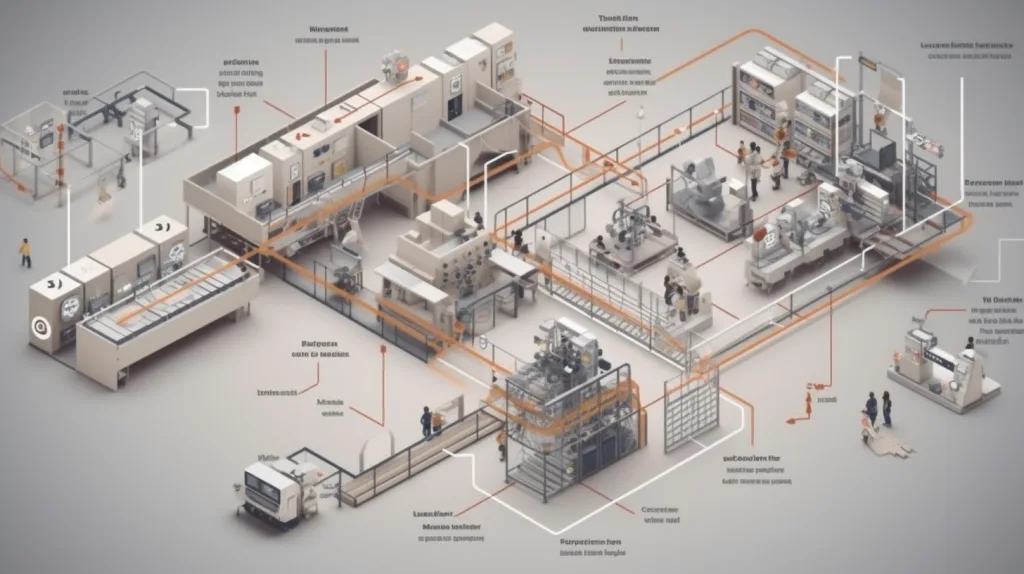

From Order to Shipment: An Overview of Our Apparel Manufacturing Workflow

When a client places an order with us, they step into a process designed to handle volume while ensuring custom attention. Here’s what the journey looks like:

1. Order Confirmation & Tech Pack Review

- We begin with a detailed review of your tech pack or design brief.

- Our sampling team checks feasibility, material availability, and customization specifics.

2. Sampling & Pre-Production Approval

- We create a custom sample within 5-7 days.

- Once approved, the sample becomes the production benchmark.

- Adjustments can be made quickly thanks to our in-house pattern makers.

3. Bulk Material Procurement

- Our sourcing team immediately locks in fabric, trims, and accessories.

- Preferred suppliers and bulk pricing agreements ensure speed and quality.

4. Production Slot Allocation

- Orders are slotted into our weekly production calendar.

- Our factory floor handles multiple lines for T-shirts, hoodies, POLOs, and activewear, allowing for category-specific scheduling.

5. Cutting & Sewing Operations

- Auto-cutting machines handle precise bulk cutting.

- Garments are sewn in progressive bundles to streamline workflow and track quality.

6. Quality Checks at Multiple Stages

- We implement QC after cutting, midway through sewing, and during finishing.

- Any deviation from the approved sample triggers a real-time correction loop.

7. Final Finishing & Packaging

- Steam pressing, label attachment, folding, and polybag packing are done in-house.

- We customize packaging based on your brand’s guidelines.

8. Dispatch & Logistics Coordination

- Once packed, shipments are coordinated through sea or air, depending on urgency.

- We assist with export documentation and offer drop-shipping if needed.

Key Systems Behind Our Large Volume Apparel Process

To support a consistent monthly clothing factory output exceeding 100K units, we rely on technology, team structure, and workflow optimization.

ERP Integration for Real-Time Tracking

Our Enterprise Resource Planning (ERP) system keeps every department aligned:

- Material availability, order status, and machine allocation are visible in real time.

- Delays or shortages are flagged instantly for resolution.

Parallel Production Lines

Instead of overloading a single line, we split orders across parallel lines:

- For example, a 10,000 hoodie order may be split into 4 lines.

- This reduces lead time and spreads quality control more evenly.

Modular Team Assignments

Each team works like a cell within the factory:

- Dedicated cutting, sewing, and QC units for each category.

- Teams are rotated to reduce fatigue and maintain speed.

Handling High Volume with Flexibility

Even with large orders, we remain committed to small brand flexibility. Here’s how:

Low Minimum Orders, High Scalability

- We accept small MOQ (as low as 100 units) for new clients.

- The same systems that support 100K+ units allow us to scale up when your brand is ready.

Fast Reorder & Recolor Cycles

- Once your style is set, we can reproduce in alternate colors or sizes with minimal lead time.

- Our material libraries and supplier relationships make it seamless.

Client-Centric Customization Support

- From embroidery to heat-transfer prints and hangtags, we adjust workflows for your branding needs.

- Our merchandisers stay in close contact for updates and approvals.

Real-World Scenarios: Brands We Support

1. Sports Team Apparel: We produced 30,000 moisture-wicking jerseys in under 25 days for a league in Southeast Asia.

2. Resort Retail Chains: Monthly delivery of 15,000 beachwear items across multiple SKUs with personalized packaging.

3. Startup Fashion Labels: Supported a new brand’s first collection of 800 T-shirts, then scaled them to 12,000 units within three months.

Why It Works: Culture of Efficiency & Transparency

At Ninghow, our process is lean not only in structure but in mindset:

- Daily Standups: Line managers share progress, address bottlenecks.

- Feedback Loops: Clients are looped into production stages with photos and videos.

- Kaizen Culture: Continuous improvement is encouraged across all departments.