Athleisure vs Performance: Product Strategy & Margin

The lines between athleisure and performance wear shape how brands design, price, and market apparel. Understanding these categories is vital for brands and buyers seeking to balance style, function, and profit. This guide details athleisure vs activewear with a focus on real-world use, technical differences, price tiers, margin math, and how to curate a winning capsule collection.

Defining Athleisure vs Activewear: Consumer Use-Cases

Athleisure combines the relaxed look of streetwear with the comfort and stretchiness of sports clothing. People wear athleisure for errands, travel, casual outings, or work-from-home days. Picture joggers paired with a denim jacket or a polo with clean sneakers—these pieces serve both comfort and style.

Activewear focuses on technical performance. It is engineered for demanding sports or fitness activities like running, gym sessions, cycling, tennis, or soccer. Here, moisture-wicking, shape retention, and freedom of movement matter most. These garments tackle real sweat, impact, and wash frequency.

- Athleisure: Everyday social occasions, relaxed office, streetwear, casual travel

- Activewear: Sports teams, training, gyms, outdoor adventure, competition settings

Fabric & Construction: Technical Differences That Matter

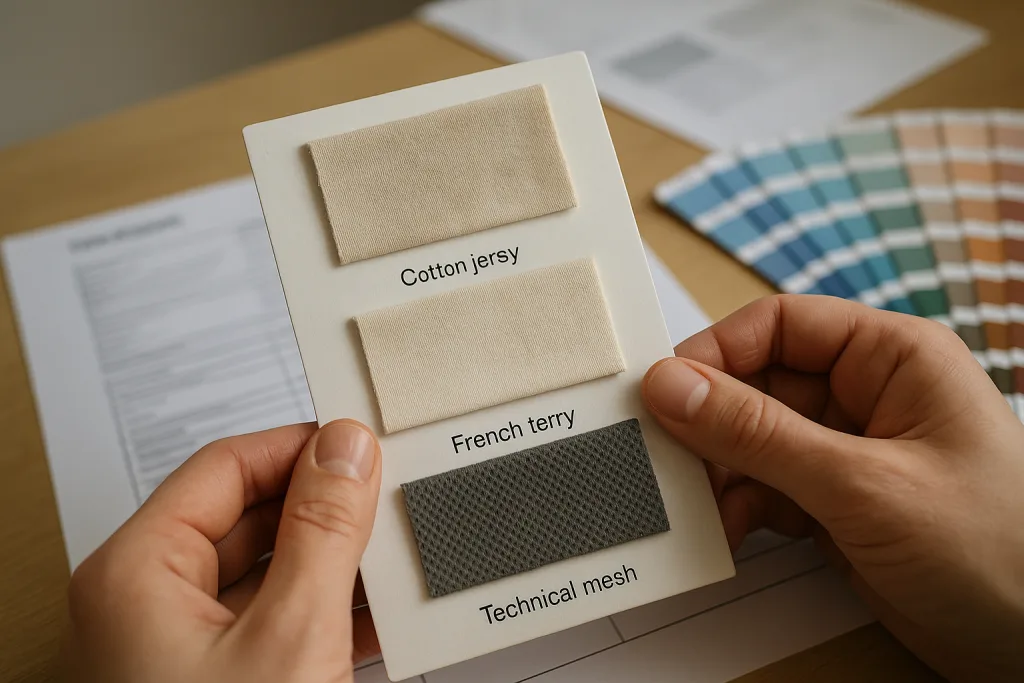

The choice of material directly impacts performance, handfeel, longevity, and price. Let’s compare the construction of athleisure and technical activewear.

| Category | Typical Fabrics | Key Properties | Common Constructions | Best Use-Case |

|---|---|---|---|---|

| Athleisure | Combed cotton (20s-32s), modal, blended jersey, French terry, fleece (280–340gsm) | Soft hand, breathability, easy care, gentle stretch | Single jersey knit, loopback, peach finish | Lounging, travel, casual wear |

| Activewear | Polyester (rPET), nylon, elastane (spandex) blends, technical mesh (160–220gsm) | Moisture-wicking, quick dry, high recovery, odor control | Interlock knit, mesh panels, flatlock seams, bonded hems | Sweat, athletic events, training |

Why Technical Details Influence Price

Performance fabrics like GRS-certified recycled polyester, or blends with 10–20% elastane, cost more than basic cotton. Technical finishes—such as moisture-wicking, UV protection, or anti-odor treatments—involve extra lab work and quality checks (e.g., colorfastness to ISO 105 standards, pilling resistance per ISO 12945).

Ninghow’s Approach

Ninghow offers trims and constructions aligned to each use-case: coverstitch for activewear seams, double-needle hem for athleisure, and pre-shrunk treatment to reduce post-wash surprises. Fabrics are sampled and tested to meet demanding B2B requirements for fit, handfeel, and durability.

Durability, Handfeel & Testing: Making the Grade

Performance activewear must pass stability, burst, and seam strength tests (see ASTM D1683). Athleisure leans toward soft touch—think brushed french terry or peach-finished cotton—tested for pilling and shape retention to withstand frequent casual use.

- Color Stability: Pantone-matched lab dips, bulk shade control, and washfastness to AATCC standards

- Shape & Fit: Graded size sets, tolerance checks, pre-production samples

- Handfeel: Brush, sand, and enzyme washes for comfort (athleisure); technical mesh, cooling finish for activewear

Merchandising a Capsule: Planning for Margin & Versatility

Athleisure and performance capsules each follow distinct planning rules. A capsule is a focused product drop—maybe six to ten SKUs—covering core needs for a target buyer. Brands aim to maximize average order value and cross-selling.

Athleisure Capsule Blueprint

- Essential tee (single jersey cotton, 160gsm)

- Everyday jogger (brushed French terry, 280gsm)

- Crewneck sweatshirt (fleece or modal blend, peach finish)

- Polo shirt (ring-spun cotton or piqué, rib collar)

- Zip hoodie (fleece, 320gsm, YKK zippers for reliability)

- Hybrid short (woven poplin or nylon, casual cut)

Activewear Capsule Blueprint

- Moisture-wicking tee (poly-elastane blend, interlock knitting)

- Compression short (nylon, 20% elastane, seamless front gusset)

- Training jogger (technical mesh back panels, zip pocket)

- Performance hoodie (poly fleece, thumbhole cuffs, UPF-treated)

- Tank top (breathable mesh, flatlock seams)

- Warm-up jacket (polyester shell, bonded panels, reflective trim)

Cross-merchandising these capsules (e.g., pairing a technical base layer under a brushed crewneck) can drive up basket size while targeting buyers who want a little of both worlds.

Pricing Bands & Cost-to-Margin Math

Price and margin vary by complexity, materials, and perceived value. Athleisure typically starts at a lower cost base, while branded performance wear can command premium prices due to R&D and compliance.

| Category | Entry FOB Cost (USD) | Blended Retail Price | Typical Gross Margin |

|---|---|---|---|

| Athleisure Tee | $2.40–3.20 | $18–35 | 70–82% |

| Performance Tee | $3.80–5.90 | $30–55 | 68–78% |

| Athleisure Jogger | $5.20–6.00 | $40–80 | 70–80% |

| Performance Legging | $7.20–10.00 | $55–110 | 65–76% |

Margin Drivers to Watch

- Material cost (cotton/modal vs. recycled poly or high elastane blends)

- Decorations: High-density screen print, DTF, and heat transfer for bold branding in athleisure vs. subtle transfer or laser-cut logos for performance

- Testing & Compliance: OEKO-TEX, GOTS, and CPSIA add assurance—and cost—for technical activewear

- Order size (MOQ), color variety, and seasonal refreshes

Ninghow helps brands model full landed cost scenarios (including import freight, duties, packaging) for precise margin targets on both athleisure and performance lines.

Styles, Patterns & Decoration: What Sets Each Category Apart?

Design details build brand identity and reinforce the category. Athleisure favors looser cuts, milder branding, and a neutral palette inspired by street trends or seasonal color drops. Performance pieces use ergonomic patterns for a close fit, bold color pops, and functionality—like mesh venting or reflective prints.

Patterns & Cutting

- Activewear: High precision tech packs, tight tolerance markers, laser grainline alignment for stretch recovery

- Athleisure: Relaxed fits, softer drape, less seam complexity

Decorations & Branding

- Activewear: Heat-seal, reflective transfer, subtle embroidery in high-stress zones (shoulders, thigh panels)

- Athleisure: Puff embroidery, large placement screen prints, direct-to-film for quick trends

Production Lead Times & Logistics

Speed to market matters. Athleisure can move faster—fabrication is often less complex, requiring fewer lab dips or test runs. Sample-to-bulk lead times average 28–50 days, with a two-step fit and color approval process. Performance products need more sample rounds for lab testing, size grading, and compliance. Lead times here stretch to 45–75 days, especially with custom trims or advanced finishing.

- Sampling: Athleisure—swatch, fit, TOP (top of production). Active—add lab dips, strike-offs, multiple pre-production (PP) samples.

- Packaging: Recycled polybags on premium lines, ratio size packs, and EAN/UPC barcoding for retail drops.

- Compliance: Export documents, batch traceability, and restricted substance certifications (e.g., OEKO-TEX STANDARD 100).

Quality Control: Minimizing Returns and Protecting Brand Value

QC starts with in-line fabric inspection (checking GSM, hand, and width) and continues through pattern audits, sewing (SMV-balanced lines), and end-of-line spec measures. Key points:

- Measurement specs (body length, chest, sleeve) checked per tolerance table (±1cm standard for knits)

- Puckering and seam stretch tested for both categories

- Needle detection for bulk orders (especially for children’s activewear)

- Random AQL checks (ANSI/ASQ Z1.4, Level II: typically 2.5%) to catch defects early

Returns Risk

Poor colorfastness or shrinkage can ruin first impressions. Wash-test and dimensional stability checks prior to shipment safeguard reputation in both athleisure and activewear capsules.

Brand Spotlight: Ninghow’s Approach to Margin and Merchandising

Ninghow supports brands from tech pack to final delivery. Key services include sustainable fabric sourcing (organic, GRS rPET), bulk Pantone/strike-off control, flexible MOQs (200–600pcs), and fast fit/sample approval streams. Whether supporting a street-inspired athleisure drop or a technical team kit, all processes—from spec table writing to carton marking—aim for total consistency and a fit-for-purpose final product.

Expert Takeaway: Strategic capsule planning—combining core essentials with brand-right technical skills—helps both start-ups and global brands capture margin and deliver quality at scale. Choosing the right fabric, trim, and process for each piece makes the difference between casual commodity and lasting loyalty.

Future Trends: Where Athleisure and Performance Intersect

Hybridization is taking over. Expect more products that blend technical features into everyday silhouettes: a stretch chino with moisture-wicking, or a hoodie with mesh zones for ventilation. Sustainability, customization, and smarter trims (reflective, anti-odor, recycled content) have become must-haves, not options. Brands who master both the margin math and real-user needs will lead the next cycle.

- Bio-based fibers and waterless dye processes

- Quick-turn DTF prints for trend updates

- Smarter supply chains using predictive data on capsule sell-throughs

Frequently Asked Questions

What’s the main difference between athleisure and activewear?

Athleisure focuses on style and comfort for everyday wear, while activewear is engineered for serious sport and performance needs.

Which fabrics work best for athleisure vs activewear?

Athleisure uses soft cotton, modal, or French terry; activewear employs moisture-wicking polyesters, nylon, and elastane blends for stretch and durability.

Do athleisure products have better profit margins than activewear?

Often yes, because athleisure requires less technical fabric and testing, resulting in lower manufacturing costs and easier price scaling.

Which performance finishes add the most value?

Moisture-wicking, anti-odor, and UPF protection are top choices, increasing product appeal and helping justify higher retail pricing.

How can brands minimize returns on these product lines?

Brands should focus on accurate sizing, thorough lab testing, quality control at every stage, and clear garment care instructions.

Is it possible to blend both categories in one capsule?

Yes—many brands now offer hybrid capsules combining everyday style with technical features, meeting consumers’ needs for versatility and performance.