Introduction to Sportswear Tech Packs

In today’s fast-moving sportswear industry, a detailed tech pack is your secret weapon. Whether you’re designing hoodies, polos, or performance shorts, a clear tech pack streamlines communication and minimizes costly mistakes. The sportswear tech pack template sets the stage for precise manufacturing, clear expectations, and smooth sampling. In this guide, you’ll learn the essential sections, see real-world examples, and get a free downloadable template from Ninghow—a trusted OEM/ODM clothing manufacturer known for quality and craftsmanship.

What is a Sportswear Tech Pack Template?

A sportswear tech pack template is a structured document that details every aspect of your garment design. It’s the blueprint for production, covering fabrics, trims, branding positions, size specs, tolerances, and stitch details. Tech packs help manufacturers like Ninghow understand exactly what you want, from color and fit all the way to label placement and packaging. With a complete template, your ideas become actionable for factories anywhere in the world.

Why Are Tech Packs Crucial?

- Prevents costly errors and revisions

- Standardizes approvals from sample to bulk orders

- Shortens lead times by reducing back-and-forth

- Supports quality control and compliance with standards

- Helps negotiate MOQs and pricing with clarity

Applications by Category

- Performance sportswear: Golf polos, gym T-shirts, track pants

- Lifestyle: Hoodies, sweatshirts, casual shorts

- Team uniforms: Custom colors, logo placements, exact fits

- Promotional events: Branded tee shirts, caps, giveaway apparel

- Resort and beachwear: Quick-dry swim shorts, rashguards

Essential Sections of a Sportswear Tech Pack Template

A robust tech pack covers much more than basic sketches. Below are the sections you should include in every sportswear tech pack template to keep your project moving and avoid delays.

Cover Page & Key Info

- Style name & code

- Designer & company info

- Season & end-use (e.g., “Spring 2025, golf”)

- Revision history (dates & changes)

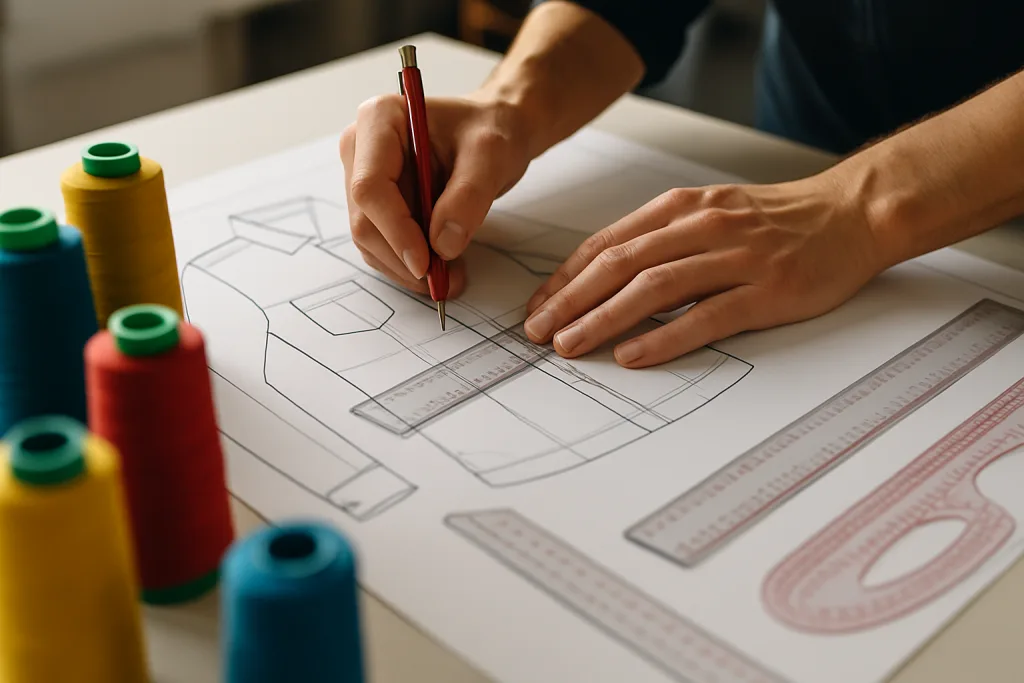

Detailed Flat Sketches

Flat sketches give manufacturers a bird’s-eye view. Include front, back, and side silhouettes. Point out pocket placements, seam details, and paneling. Hand-drawn or vector images work; just make sure lines are clear.

BOM (Bill of Materials)

The BOM breaks down every component, from main fabrics to thread types. Use a table like the one below to capture crucial info for sourcing and costing.

| Material | Type | GSM (Weight) | Key Properties | Best Uses |

|---|---|---|---|---|

| Combed Cotton | Single Jersey | 180 gsm | Soft, breathable | Tees, polos |

| Recycled Polyester (rPET) | Pique Knit | 220 gsm | Moisture-wicking | Performance golf polos |

| Cotton-Elastane Blend | French Terry | 300 gsm | Stretch, smooth handfeel | Hoodies, sweatpants |

| Organic GOTS Cotton | Interlock | 200 gsm | Sustainable, hypoallergenic | Lifestyle apparel |

Color & Artwork Specifications

Provide precise Pantone codes, lab dip references, and approved bulk shades. Call out colorfastness standards—ISO 105-C06, AATCC 61—that should be met. For prints, attach vector files and detail positions—for example, a heat transfer logo on the left chest, or full-back screen print.

Measurement Table & Graded Size Sets

Measurement charts specify each garment point for all sizes. Include tolerances—that’s the allowed variation in final manufacturing. For example, a chest width of 56 cm (L) ±0.5 cm. Document total length, sleeve length, across shoulder, and any other key dimension. Use a table:

| Measurement Point | S | M | L | XL |

|---|---|---|---|---|

| Chest | 52 ±0.5 | 54 ±0.5 | 56 ±0.5 | 58 ±0.5 |

| Sleeve | 21 ±0.3 | 22 ±0.3 | 23 ±0.3 | 24 ±0.3 |

| Body Length | 66 ±0.7 | 68 ±0.7 | 70 ±0.7 | 72 ±0.7 |

Stitch & Seam Map: What to Specify and Why

Each stitch type affects a garment’s durability, stretch, and look. Sportswear manufacturers rely on clear seam maps to produce reliable sportswear. Use labeled diagrams and callouts to show where you want ISO 301 lockstitch for shoulder seams, ISO 401 chainstitch for hems, or ISO 504 overlock for side seams. For performance jerseys or polos, specify rib collar attachment, coverstitch for hems, and bartacks at stress points.

Common Stitch Types (with Usage)

- ISO 301 Lockstitch: Used for topstitching, shoulder seams.

- ISO 401 Chainstitch: Ideal for flexible hems, waistband joins.

- ISO 504 Overlock: Seams finish for raw edges, sleeve joins.

- Bartacks: Added for pocket corners, high-stress zones.

- Coverstitch: Used to finish hems, especially on knits.

“A detailed seam map signals professionalism—it guides line balancing and machine set-up, reducing error rates.”

Tolerances and Their Role

Tolerances set the boundaries for acceptable size variation. They are vital for quality control. For example, a tolerance of ±0.5 cm means the final measurement can shift half a centimeter without rejection. Tighter tolerances mean higher precision but can affect MOQs and costs. Clearly state tolerances for each point on your measurement chart.

Decoration & Print Position Maps

Mark exact placements for embroidery, screen prints, heat transfer logos, or sublimation. Indicate maximum logo sizes, distance from seams, and color requirements. Attach artwork files in .ai, .psd, or .pdf formats. Specify technique—water-based ink for breathability, DTG for detailed graphics, or 3D embroidery for high-impact branding.

Materials & Finishes: Selection and Impact

Choosing fabric isn’t just about color or price—it affects garment longevity, handfeel, and performance. Consider the sport, climate, and end-use. For instance, Ninghow often recommends combed cotton (20s, 24s, 32s) for comfort and durability in polos or tees, and recycled polyester for moisture-wicking activewear. GSM matters: a heavier fleece (320–360 gsm) suits autumn jackets, while a lighter jersey (160–200 gsm) breathes better in summer tees. Finishes like anti-odor or UPF protection boost technical value—and should be specified in your tech pack.

Performance Finishes Explained

- Moisture-wicking: Draws sweat from skin, speeds evaporation

- Antimicrobial: Controls odor, prolongs freshness

- UV/UPF: Shields skin with certified sun protection

- Stain-release: Eases care and cleaning

- Brushed backer: Adds warmth and softness to fleece, terry

Testing & Certifications

Confirm fabrics pass required lab tests: colorfastness (ISO 105-C06, AATCC 61), dimensional stability (AATCC 135), pilling resistance (ISO 12945), and seam strength (ASTM D1683). For eco-friendly lines, request OEKO-TEX STANDARD 100 or GOTS certification. Ninghow provides full lab reports for bulk runs, keeping brands covered on compliance. Learn more about OEKO-TEX STANDARD 100.

Spec Measurement Table: The Foundation of Fit

Size specs are often the make-or-break for sportswear brands. Draft your measurement table with reference to your target market—Euro, US, or Asia fits. Include not only chest, waist, and inseam but also sleeve circumference, armhole drop, collar width, and bottom opening. Update specs after fit samples, and communicate changes with a revised tech pack.

Graded Size Sets

Provide specs for all ordered sizes, including kids, plus, or tall fits. Use graded rules (difference between sizes) for consistent scaling. For example, chest increases by 2 cm between M and L; sleeve length by 1 cm.

Tolerance Chart

List tolerances next to each measurement so QC inspectors know when a garment passes or fails inspection.

How to Build Your BOM (Bill of Materials)

The BOM is the foundation for sourcing, costing, and quality assurance. Document every input: shell fabric, rib, drawcords, zippers, buttons, thread, and labels. Note supplier IDs, material weights, colors, and treatments. For example, shell—220 gsm recycled polyester, rib—98% cotton/2% elastane, label—woven, OEKO-TEX certified.

Sample BOM Table Format

| Component | Supplier | Code | Color | Certifications | Remarks |

|---|---|---|---|---|---|

| Main Fabric | ABC Textiles | RP-220 | Pantone 289C | OEKO-TEX | Recycled Poly |

| Rib | XYZ Knits | KN-32 | Pantone 11-0601 | GOTS | Cotton/Elastane |

| Zipper | YKK | VIS-06 | Black | REACH | 6″ coil |

Why BOM Matters

- Sets accurate costing for production

- Defines sustainable sourcing (GOTS cotton, rPET)

- Controls consistency across sample and bulk

- Simplifies lab testing and compliance traceability

Print Positions & Decoration Techniques in Sportswear Tech Packs

Your sportswear tech pack template should have a dedicated section for branding and artwork. Map out decorations: embroidery on left chest, screen print down right sleeve, DTF logo on back neck, or puff embroidery on cap fronts. Call out technique (e.g., water-based screen print for breathability, or sublimation for all-over prints on poly). Indicate artwork file names and color specs. This level of detail prevents miscommunication and keeps quality high.

Decoration Methods Comparison

| Technique | Handfeel | Durability | Best Uses |

|---|---|---|---|

| Screen Print (Plastisol) | Thicker, raised | Very durable | Bold graphics, logos |

| Water-based Print | Soft, thin | Lasts through moderate washing | Lightweight sports tees |

| Sublimation | Smooth, integrated | Permanent on polyesters | All-over prints, team kits |

| Embroidery | Textured | Colorfast, resists fade | Polo logos, caps |

| DTG (Direct to Garment) | Soft, photographic | Lasts 30+ washes | Custom, small batch tees |

Expert Takeaways

“Specified print position and technique ensure final garments match branding goals and customer expectations. Always attach artwork with scale references.”

Packaging, Labelling & Logistics Details

A comprehensive sportswear tech pack template also covers packaging specs. Detail folding methods, polybag dimensions, hangtag and label designs, carton sizes, and packing ratios (e.g., 2S/4M/4L/2XL per box). List required barcodes (UPC, EAN), customs marks, and Incoterms terms. Ninghow’s end-to-end service means these instructions arrive with each sample and bulk order, so packing meets retail or event requirements exactly.

Key Labelling Symbols

- Washing instructions (ISO 3758 icons)

- Material content percentages

- Country of origin

- Size, style code, batch number

Sportswear Tech Packs 101 (Free Template Inside)

Ready to build your own? Download Ninghow’s purpose-built sportswear tech pack template and get started. The template bundles all sections—cover page, flat sketches, BOM, measurement chart, tolerances, seam map, print positions, packaging specs—into a single, editable file. Designed for sportswear, lifestyle, and corporate programs, this template speeds up sampling and production. Request yours today to streamline approvals, boost fit consistency, and enhance quality. Download Ninghow’s free sportswear tech pack template.

Frequently Asked Questions

What is a sportswear tech pack template?

A sportswear tech pack template is a detailed document that guides manufacturers on materials, measurements, decorations, and production details for sports apparel.

Why does BOM matter in a tech pack?

The BOM lists all materials and trims used, setting the foundation for accurate costing, sourcing, and quality assurance during manufacturing.

How do tolerances impact production quality?

Tolerances specify allowed measurement variations, ensuring garments meet quality standards without unnecessary rejections or remakes.

Should I include decoration positions in my tech pack?

Yes, mapping print and embroidery positions avoids miscommunication and ensures artwork is placed accurately on every finished garment.

How can I ensure fabric meets performance standards?

Request lab testing for properties like colorfastness, dimensional stability, and certifications like OEKO-TEX or GOTS for sustainable options.

Where can I get a free sportswear tech pack template?

You can download Ninghow’s free sportswear tech pack template for unlimited use and customization on their official website.